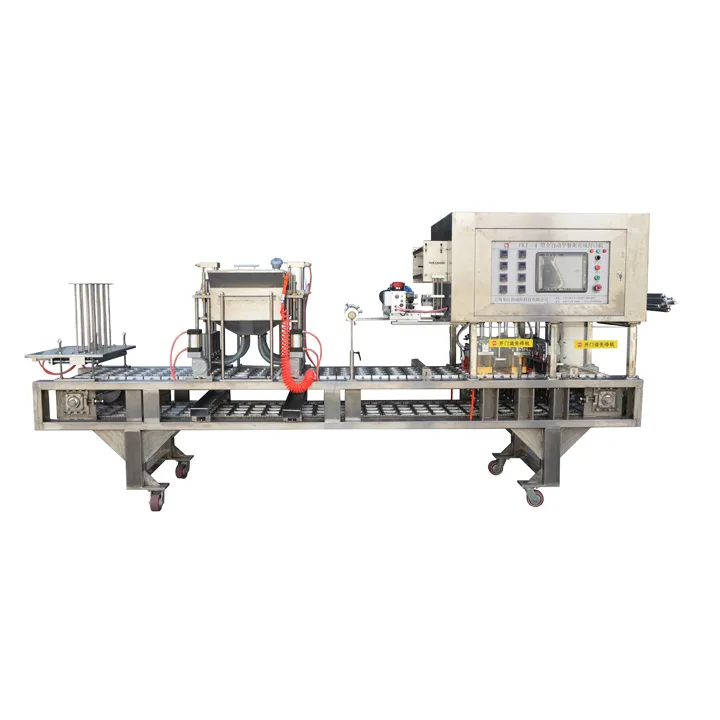

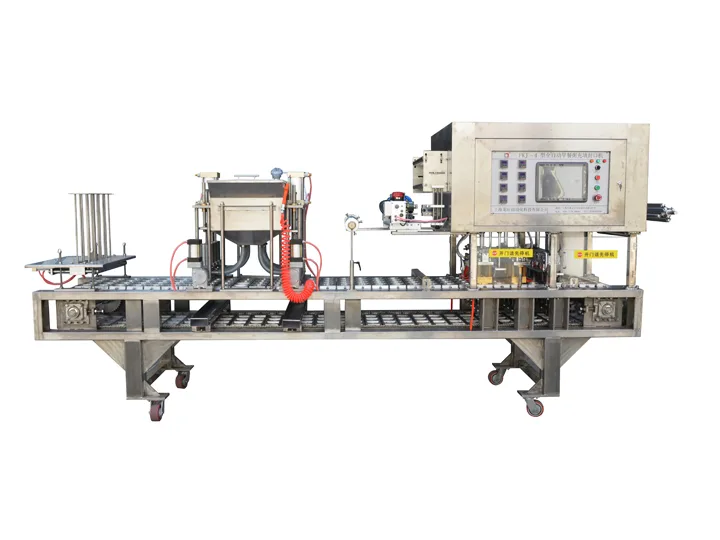

Revolutionary Packaging for Traditional Delicacies

- Core Innovations

Vacuum-Sealed Freshness

Integrated vacuum chamber extracts 99.9% air before sealing

Oxygen barrier extends shelf life by 3x vs. conventional packaging

Preserves soft texture and prevents moisture loss

Sticky-Proof Engineering

Non-stick coating on hopper/filling nozzles

Patented piston design handles ultra-high viscosity (up to 500,000 cP)

Zero-residue discharge after filling

Thermal Sealing Excellence

Dual-mode sealing:

Low-temp mode: 70-90°C (preserves delicate texture)

High-barrier mode: 120-150°C (enhanced seal integrity)

Wrinkle-free sealing even on uneven surfaces

- Industry-Unique Advantages

✅ Texture Preservation Technology

Pulse vacuum control prevents deformation of delicate cakes

Gas flushing (N₂/CO₂) optional for premium products

✅ Anti-Contamination System

Self-clearing filling nozzles eliminate cross-batch residue

Food-grade conveyor belts with crumb collection

✅ Smart Production

AI-powered weight compensation (adjusts for density variations)

IoT-enabled predictive maintenance

- Application-Specific Design

Custom Tray Molds: Round/oval/square shapes (100-1000ml)

Multi-Layer Filling: Sequential deposition of rice, beans, jujube paste

Steam Control: Optional steam injection to maintain product temperature

- Target Markets

Traditional Chinese pastry manufacturers

Ready-to-eat meal producers

Premium gift food brands

Supermarket central kitchens

“Engineered for the world’s stickiest challenge”, this machine solves critical Zeng Cake packaging pain points:

✦ Air pockets elimination

✦ Shape integrity maintenance

✦ Starch adhesion prevention

✦ Scalable artisanal production

Contact us for a live demo – Experience how tradition meets automation!