Our ice cream production line is a modern food processing system integrating automation, efficiency, intelligence, and hygiene. Designed to meet the needs of ice cream manufacturers of various scales, it enables continuous and stable completion of the entire process from raw material mixing to finished product packaging, producing ice cream with consistent quality, rich texture, and diverse forms.

Core Equipment Composition & Function

A complete ice cream production line typically includes the following key equipment, which can be customized according to client requirements:

Raw Material Handling System:

Storage Tanks: For storing liquid ingredients (milk, cream, syrup, water, etc.).

Powder Dosing/Dissolving System: For precise weighing, dosing, and dissolving of dry ingredients (milk powder, stabilizers, emulsifiers, etc.). (Vacuum dissolution optional for improved efficiency).

Ingredient Metering & Conveying System: Precisely meters various liquid and dissolved ingredients, pumping them to the mixing unit.

Mixing & Pasteurization System:

Mixing Tank/Pasteurizer: A core unit.

Mixing: Thoroughly blends all ingredients.

Pasteurization: Eliminates pathogenic and most spoilage microorganisms at specific temperatures/times (e.g., 80-85°C, 15-30 sec), ensuring food safety.

Homogenization: (Typically done immediately after pasteurization) A high-pressure homogenizer breaks fat globules into smaller particles, resulting in a smoother mix texture, creamier mouthfeel, and improved stability (prevents fat separation).

Aging System:

Aging Tanks: Store the pasteurized and homogenized mix at low temperatures (typically 0-4°C) for a set duration (typically 4-24 hours).

Function: Allows fat crystallization, protein hydration, and stabilizer hydration, increasing mix viscosity and overrun. This yields a richer final product taste, more stable structure, and better melt resistance.

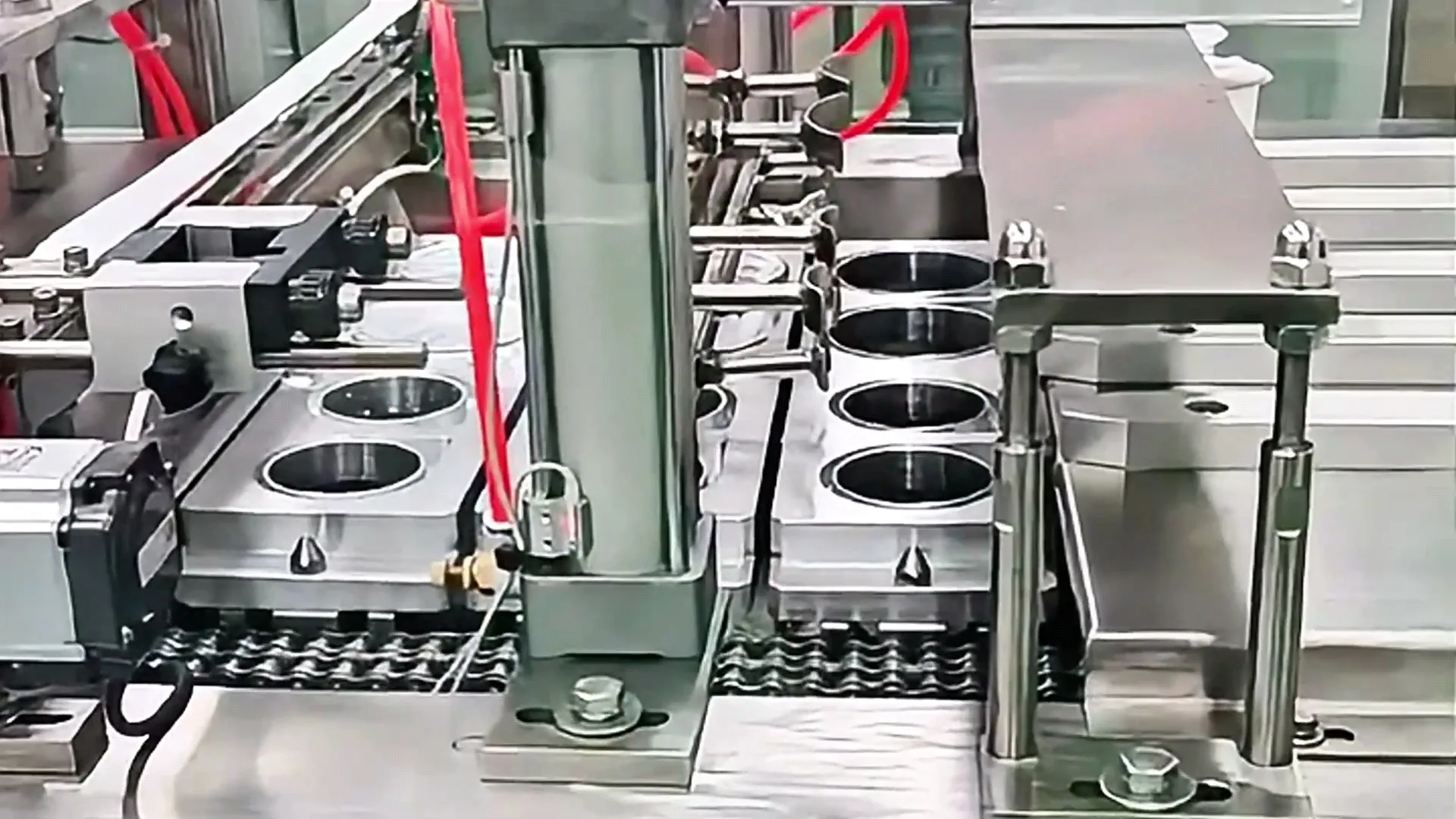

Freezing System – The Core of Ice Cream Production:

Continuous Freezer: The heart of the line.

Function: Freezes the aged mix at low temperature (approx. -6°C) while simultaneously whipping in air (called “Overrun”), forming semi-solid, smooth-textured soft ice cream containing tiny ice crystals and air bubbles.

Key Parameter Control: Precise control of feed temperature, outlet temperature, overrun, agitation speed, etc., directly impacts the final product’s texture, mouthfeel, and output.

Types: Various models available based on output requirements (e.g., single-barrel, multi-barrel, high-capacity).

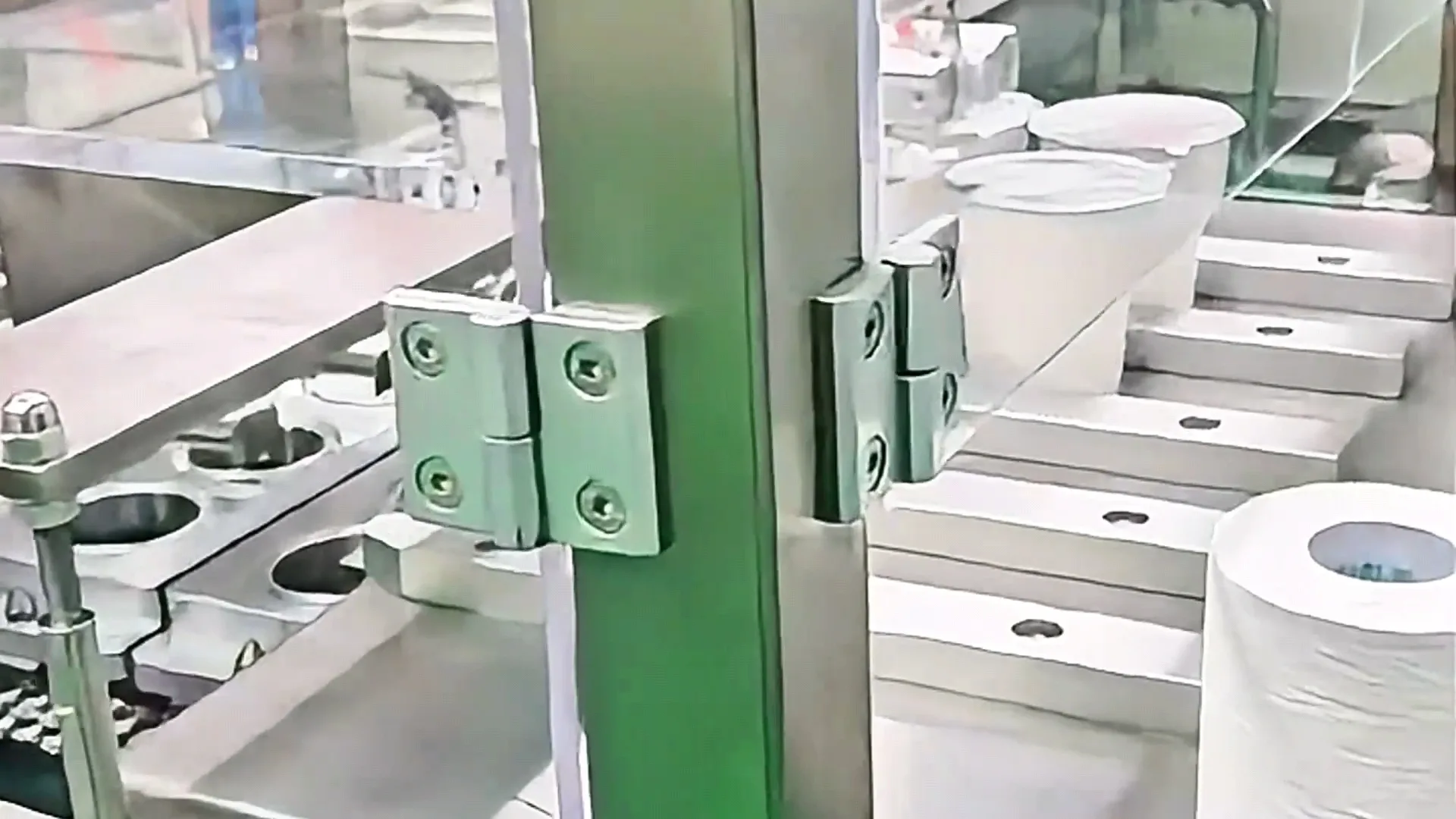

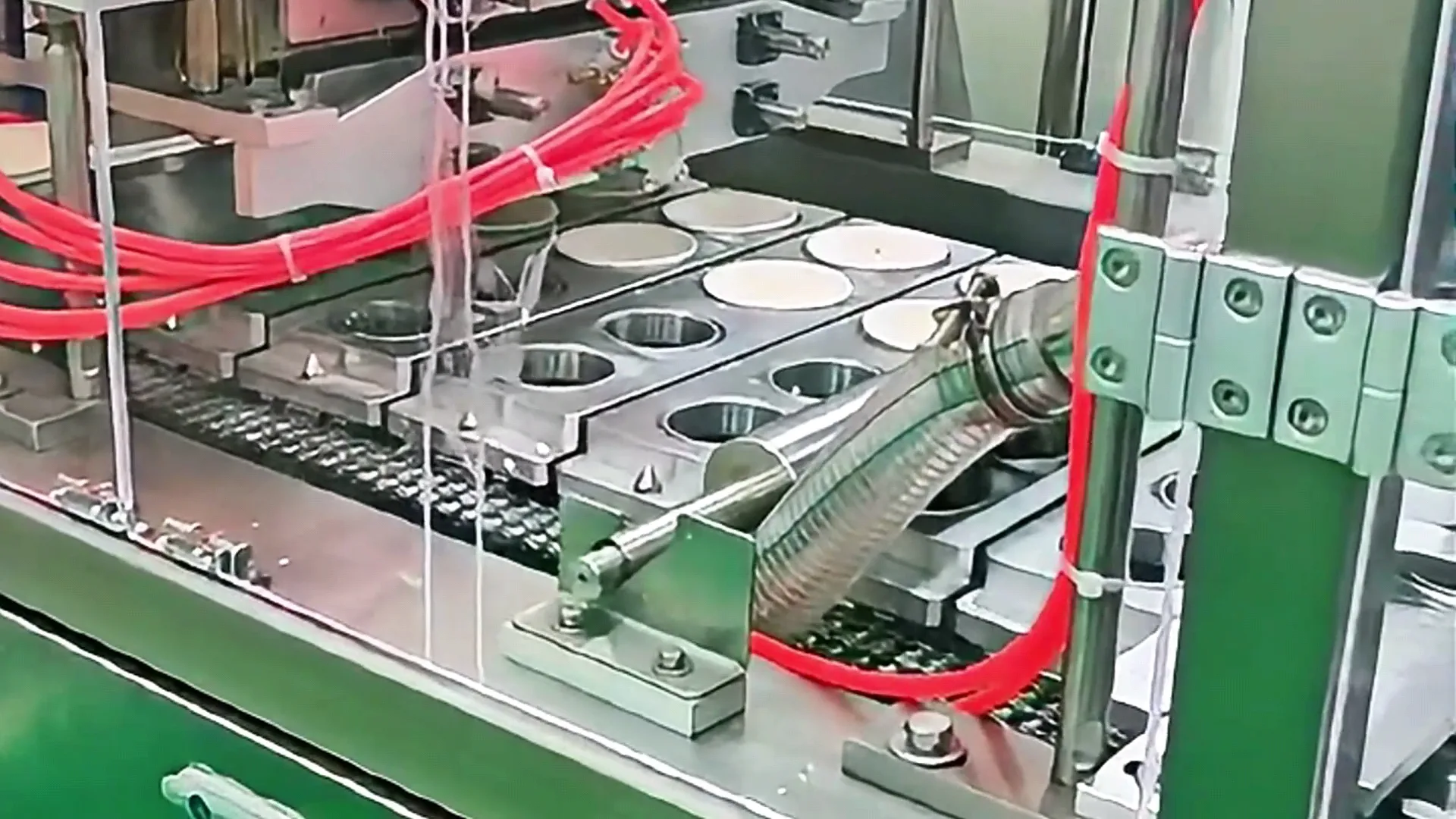

Forming & Filling System:

Equipment selection depends on product shape:

Filling Machine: Quantitatively fills frozen soft ice cream into cups, tubs, cones, family-size containers.

Extrusion Molding Machine: Produces bar-shaped, block-shaped, or novelty ice cream (e.g., sticks, filled bars). Can be combined with chocolate enrobers, jam/fruit injectors.

Novelty Ice Cream Machine: Produces stick-mounted ice cream, enabling multi-layer filling (e.g., twin-flavor) and core injection.

Pre-Hardening Treatment: For certain products (e.g., coated bars), chocolate spraying or dipping occurs before entering the hardening tunnel.

Hardening System:

Hardening Tunnel/Blast Freezer: Critical equipment ensuring product quality and shelf life.

Function: Rapidly deep-freezes formed or filled soft ice cream products to a core temperature of -18°C or lower within a very short time (typically 30-60 minutes).

Purpose: Fully sets the product, forms a fine ice crystal structure (maintaining smooth texture), prevents ice crystal growth during storage (which degrades quality), and inhibits microbial growth, extending shelf life.

Types: Spiral, straight-line tunnels, or large blast freezers. Typically uses ammonia or Freon refrigerant, reaching temperatures of -35°C to -45°C.

Packaging System:

Multi-Functional Packaging Machines: Automatically package the hardened ice cream products.

Types: Flow wrappers (for sticks), cartoners, wrap-around packers (for tubs), cup sealers, case packers, etc.

Function: Provides product protection, extends shelf life, enhances brand image, facilitates transport/sales. Can integrate date/batch code printing.

Control System:

PLC + HMI + SCADA: The “brain” of the entire line.

Function: Centralized monitoring and control of all equipment parameters (temperature, pressure, flow, speed, level, etc.), recipe management, production data logging, fault alarm/diagnosis, enabling automated operation and remote monitoring.

Advantages: Increases production efficiency, guarantees consistent product quality, reduces human error, facilitates production management and traceability.

CIP (Cleaning-In-Place) System:

Function: Provides automated, in-line cleaning and sanitization programs, ensuring line hygiene and safety, complying with food production standards (e.g., HACCP, GMP).

Composition: CIP tanks (acid, alkali, hot water, rinse water), pumps, piping, valves, control system. Can automatically clean mixing, pasteurization, aging, and freezing sections.

Line Features & Advantages

High Automation: Significantly reduces labor dependency, increases efficiency, lowers labor costs and operational risks.

Continuous Production: Seamless integration of processes enables efficient, stable, continuous output.

Exceptional Product Quality: Precise process control (temperature, time, overrun, etc.) ensures a smooth texture, stable structure, pure flavor, and minimal ice crystals.

Flexible Customization: Customizable for capacity (from hundreds to tens of thousands of liters per hour), product type (soft-serve, hard ice cream, cups, tubs, sticks, novelties), automation level, and packaging format.

Stringent Hygiene Standards: Equipment made from food-grade materials (e.g., SUS304/316L stainless steel), designed for easy cleaning, standard CIP system ensures food safety.

High Efficiency & Energy Savings: Utilizes advanced refrigeration technology, heat recovery systems (e.g., pasteurization section), and optimized design to reduce energy consumption and operating costs.

Intelligent Management: Central control system enables data-driven, visual production management, improving traceability and management efficiency.

Reliability & Durability: Key components sourced from internationally renowned brands, robust overall design ensures long-term stable operation.

Regulatory Compliance: Design and manufacturing comply with international and target market food safety and machinery safety standards.

Application Scope

Large-scale ice cream brand manufacturers

Dairy companies expanding product lines

Medium-sized ice cream factories

Central kitchens for restaurant chains (supplying soft-serve to outlets)

Emerging ice cream startups

Why Choose Our Ice Cream Production Line?

Extensive Experience: Years of successful experience in R&D, manufacturing, and service for ice cream equipment, serving numerous renowned domestic and international clients.

Core Technology: Mastery of core technologies for key processes like freezing and hardening, ensuring leading product performance.

Turnkey Solution: Provides comprehensive services from concept design, equipment manufacturing, installation & commissioning, personnel training, to after-sales support.

Premium Service: Global service network offers responsive technical support and spare parts supply.

Continuous Innovation: Ongoing R&D in new technologies and processes helps customers enhance product competitiveness and production efficiency.

Customized Solutions: We deeply understand each client’s unique needs and are committed to providing solutions that best align with your production goals and budget.

Get More Information

If you are interested in our ice cream production line or require detailed consultation and design proposals tailored to your specific needs (target capacity, product type, budget, factory space, etc.), please contact us anytime. We are happy to provide professional advice and detailed materials.