Features & Structural Highlights

Advanced Control System:

Operated via an imported PLC human-machine interface (HMI) with touchscreen control.

Driven by seven servo motors for synchronized motion, ensuring stability at high speeds and effortless adjustments.

Precision Film Feeding:

The lower film system is servo-controlled for flexible film length adjustment, offering superior adaptability.

Features an air-expanding shaft for quick film roll changes and secure mounting, eliminating lateral wobbling (common in screw-type shafts).

Versatile Mold Compatibility:

Supports rapid mold changes for diverse rectangular box sizes, ensuring stable operation, airtight sealing, smooth aesthetics, and easy maintenance.

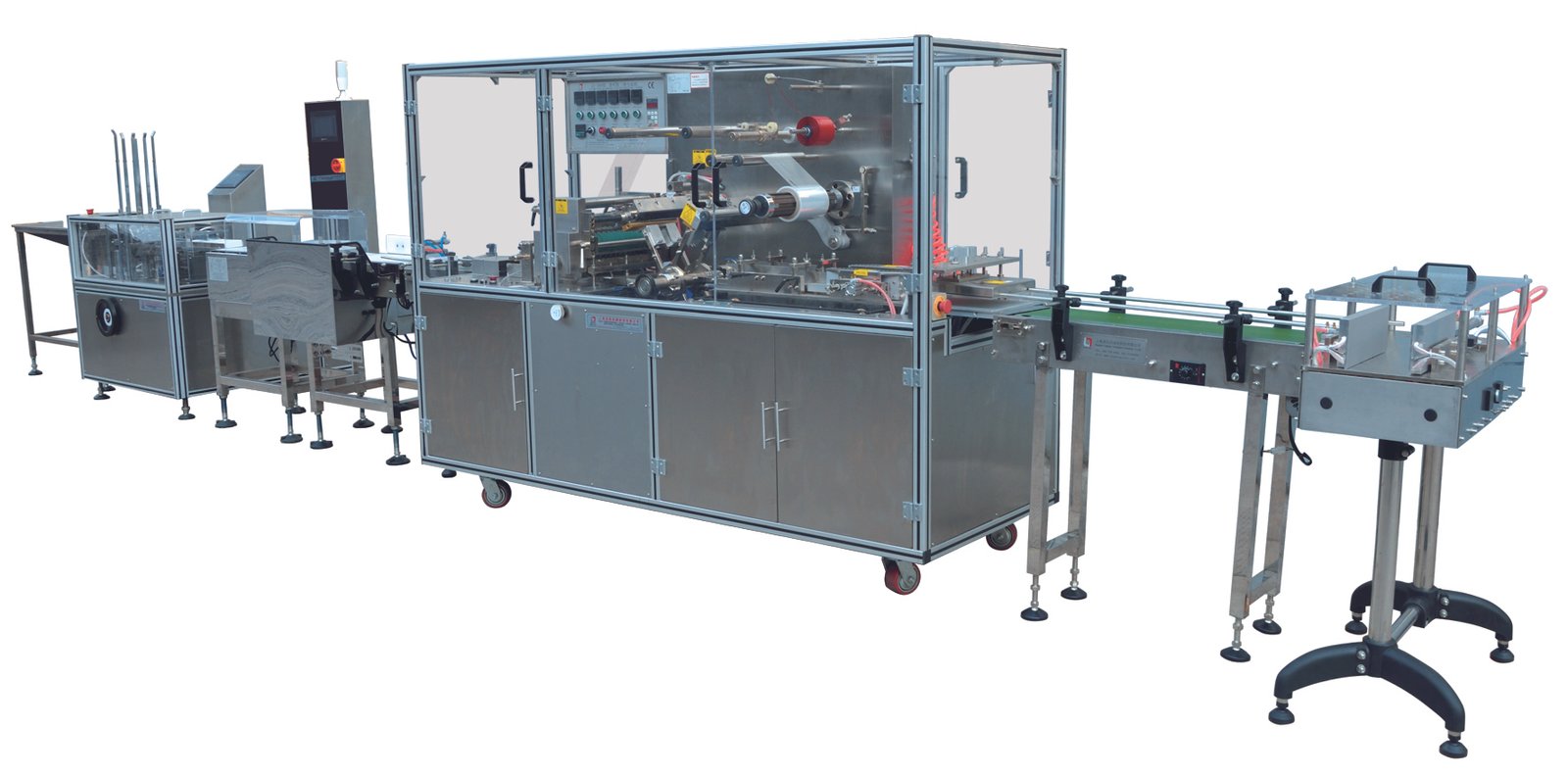

Hygienic & Robust Design:

Constructed with a durable frame and acrylic protective cover, complying with hygiene standards and delivering a sleek appearance.

Safety & Automation:

Emergency stop buttons on the operation panel and feed conveyor.

Automatic shutdown triggered by box jams via a safety mechanism on the pusher.

Intuitive HMI with manual mode (for individual component adjustments) and auto mode (with settings for speed, film length, and counting).