Core Process of Longying Porridge Production Line: Raw Rice Filling Technology

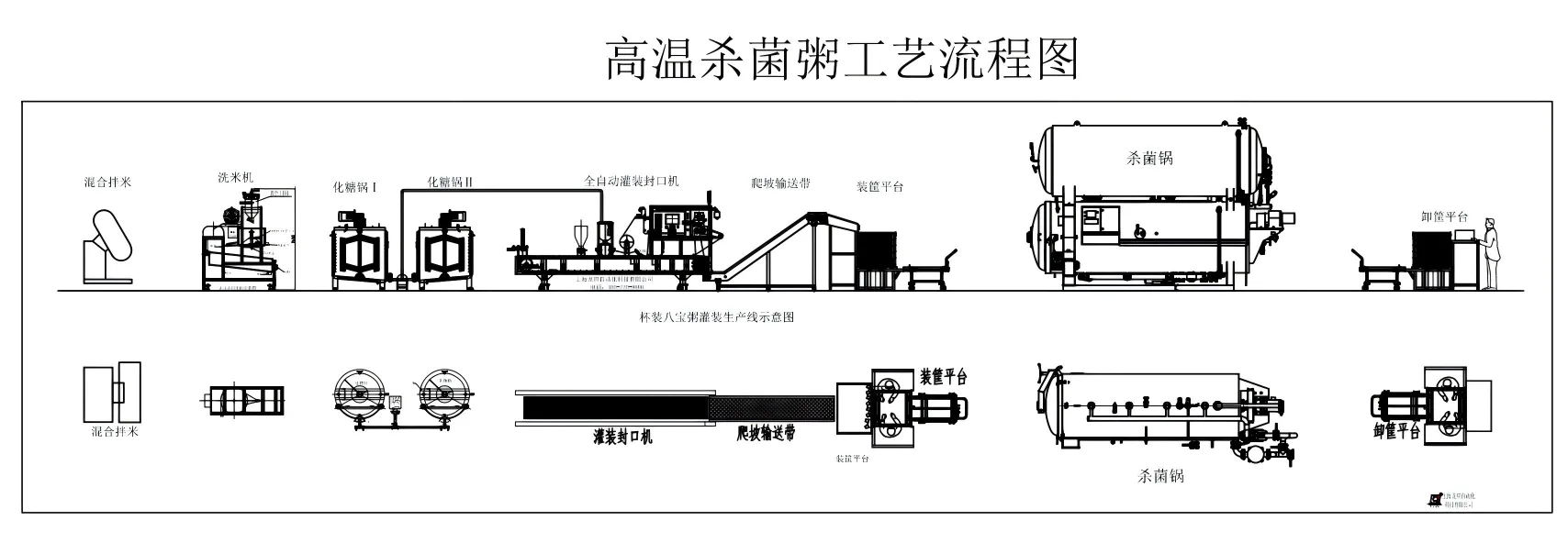

Longying porridge production line is renowned for its core “raw rice filling” process, which disrupts the traditional cooked porridge filling model. The key procedures are as follows:

Selected raw rice is measured and directly filled into clean cans/cups in precise quantities. This step is crucial to ensuring the original grain texture and nutrition of the porridge.

Accessories (such as grains, beans, diced meat, etc.) are added to the cans according to strict ratios, followed by the injection of pre-prepared flavored soup.

After sealing the cans, they are conveyed into a large rotating cooking sterilization kettle. The cans rotate inside the kettle to ensure uniform heating, enabling the contents to gelatinize and cook thoroughly, while completing high-temperature and high-pressure sterilization. In this stage, raw rice is transformed into soft and palatable porridge.

After gradient cooling, the cans are labeled and boxed to form the final products.

Advantages

The combination of raw rice filling and rotating cooking locks in the original aroma and nutrition of ingredients to the greatest extent. The rice grains remain intact and plump, offering a taste closer to freshly cooked porridge. Additionally, it features a long shelf life and ensures safety and hygiene.

Longying Transparent Film 3D Packaging Machine offers an efficient and visually appealing packaging solution for the cosmetics industry. Utilizing advanced 3D wrapping technology, it precisely adapts to various cosmetic packaging types (such as lipstick cases, compacts, gift boxes, etc.), enabling fully automatic film wrapping, heat sealing, and cutting. The machine ensures a tight, seamless fit of the transparent film, enhancing product texture and shelf appeal.

Key advantages include:

High-speed & stable performance, with a capacity of 30-50 packs per minute;

Supports eco-friendly POF/PVC films, reducing material costs;

Smart adjustment system allows quick changeovers for different specifications, enabling flexible multi-product production;

Transparent packaging improves anti-counterfeiting and display effects, elevating brand premiumization.

Longying Sugar Melting Pot is a high-efficiency sugar dissolving tool crafted with ingenuity. The pot body consists of a stainless steel inner cylinder and a carbon steel outer shell forming a heat-transfer combining aesthetic appeal with durability.

Steam into the interlayer enables precise temperature control for uniform heating, preventing syrup from local overheating and coking. Equipped with a pressure gauge and safety valve, it ensures safe operation. Suitable for various materials like dairy products and syrup, it enhances sugar melting efficiency and quality.

Double-Layer Automatic Water Bath Rotating High-Temperature High-Pressure Conditioning Sterilization Kettle

The integrated material rotation inside the kettle optimizes heat utilization, achieving – free sterilization with fast and precise results.

Specifically designed for canned foods with solids heavier than liquids or various viscous concentrations, the rotation during sterilization prevents layering and sedimentation within the shelf life.

The double-layer water bath structure ensures uniform temperature distribution, while the rotating mechanism enhances heat transfer efficiency by 30% compared to traditional static kettles.

Jams, eight-treasure porridge, fruit milk, milk-containing beverages (e.g., corn milk, walnut milk, peanut milk with sediments), and other products with particulate matter or high viscosity.

A:Supports disposable cup packaging and bowl packaging.

A :

Filling methods:

Cold-Fill (for raw ingredients)

Hot-Fill (for pre-cooked congee)

A: Includes:

✓ On-site installation

✓ Technical training

✓ Turnkey project delivery

A: Starts at ~RMB 200,000, finalized based on client specifications.

A:6 months to 1 year at ambient temperature

A: 0.5 to 10 T/H (customizable).

A: Fully customizable capacity and configurations.

Mixing of Rice & Ingredients

→ Raw material blending

Washing Rice & Ingredients

→ Triple-stage rinsing

Sugar Syrup Preparation

→ Dissolving tank + filtration

Controlled-Temperature Cooking

→ *Steam-jacketed kettle (90-95°C)*

Filling

→ *Hot-fill at ≥85°C (cups/bowls)*

Automated Product Conveying

→ Incline belt with cooling zone

Pasteurization

→ *Tunnel pasteurizer (80°C/15min)*

Air-Knife Drying

→ Moisture removal before labeling

Refrigerated Storage

→ *Cold room (0-4°C)*

We are willing to serve the society with our wisdom and ability and become your trusted partner.