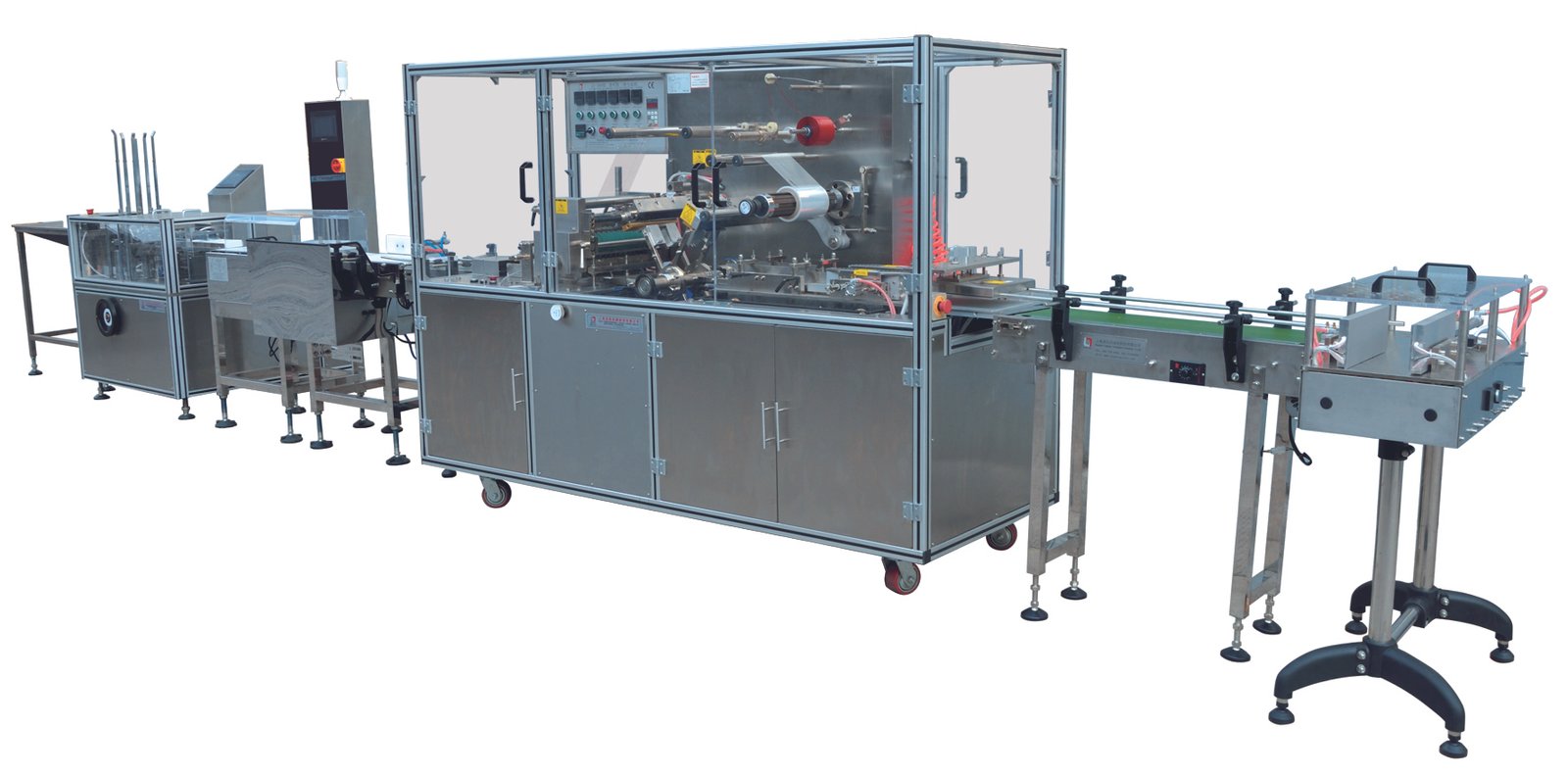

Applications

The LY-480 is widely used for single or grouped automatic packaging of boxed items in industries such as pharmaceuticals, health products, food, tea boxes, cosmetics, stationery, and audiovisual products. Products packaged by this machine gain moisture resistance, water resistance, oil resistance, dust resistance, and anti-counterfeit properties, ensuring durability during storage. It enhances product aesthetics, elevates market appeal, increases added value, and strengthens competitiveness. Utilizing low-cost materials like BOPP or PVC dual-sided heat-sealable films as primary packaging media, the machine significantly reduces material costs. Its high operational efficiency further minimizes labor and management expenses.

Functional Features

Advanced Control & Drive System:

Operated via an imported PLC human-machine interface (HMI).

Combines servo motor-driven mechanical transmission with auxiliary pneumatic components, enabling flexible speed adjustment.

Servo-controlled lower film system allows precise film length customization for superior adaptability.

Versatile Packaging & Mold Flexibility:

Accommodates rectangular boxes of various sizes with quick mold changes, ensuring stable operation, airtight sealing, smooth aesthetics, and easy maintenance.

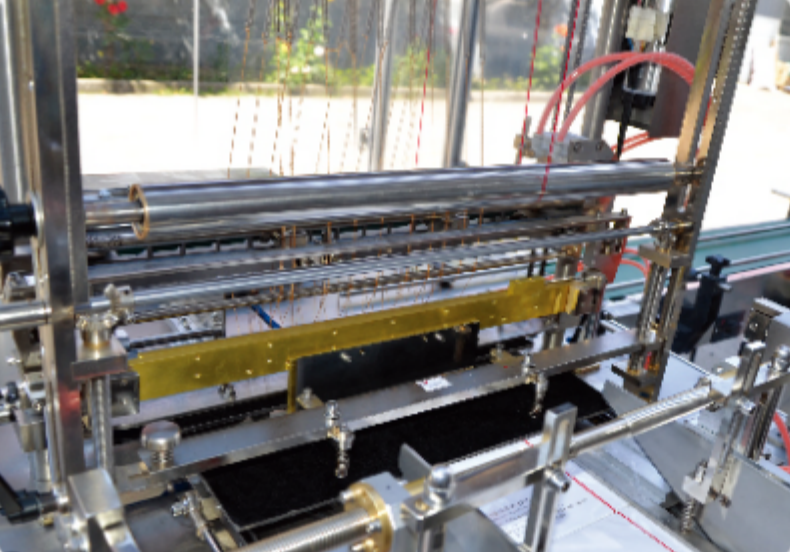

Optional automatic stacking function for multi-layer or multi-box bundled packaging.

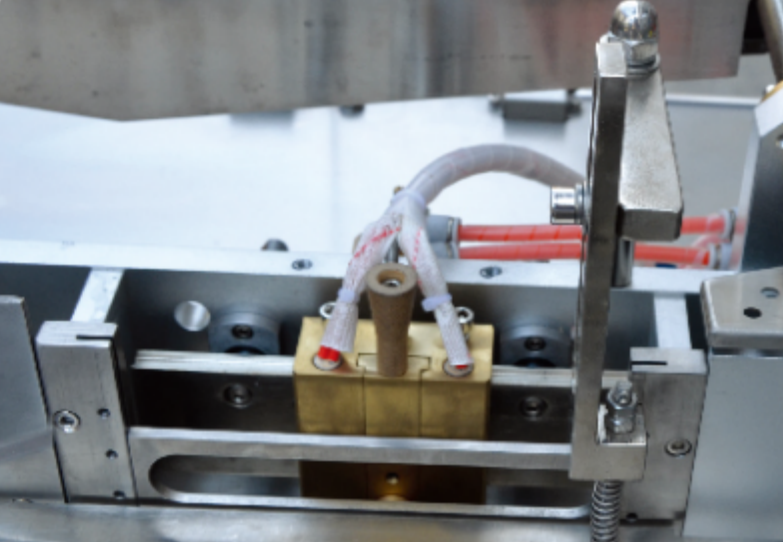

Supports dual sealing modes: spot sealing and flat sealing.

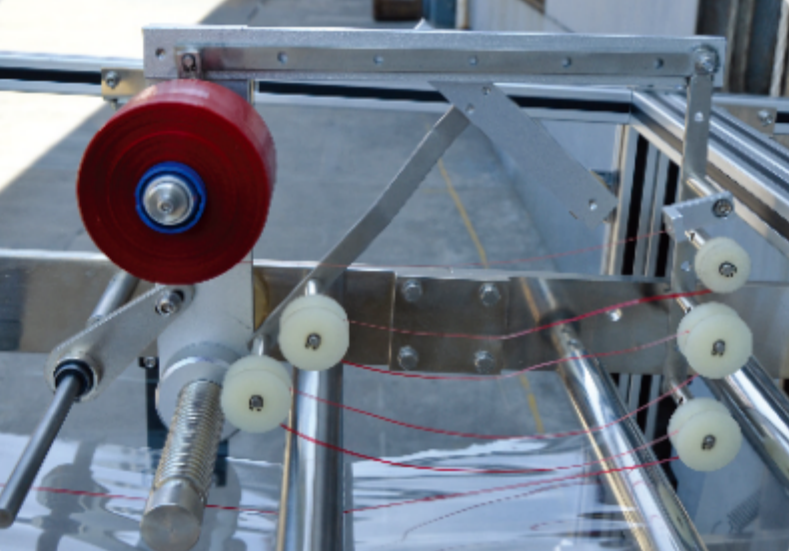

Innovative Film Unwinding Mechanism:

Pneumatic film unwinding shaft enables rapid film roll replacement and eliminates lateral wobbling during operation.

*Traditional screw-type shafts cause uneven film distribution (especially for square boxes), leading to inconsistent wrapping. The LY-480’s pneumatic shaft resolves this issue entirely.*

Durable & Hygienic Construction:

Built with an imported aluminum alloy frame and enclosed acrylic protective cover.

Contact surfaces (e.g., platform) use 304 stainless steel, complying with hygiene standards and offering a sleek, corrosion-resistant design.

Safety & Automation:

Emergency stop buttons on the operation panel and feed conveyor.

Automatic shutdown triggered by box jams.

User-friendly HMI with manual mode (for component-specific adjustments) and auto mode (speed, film length, and counting presets).