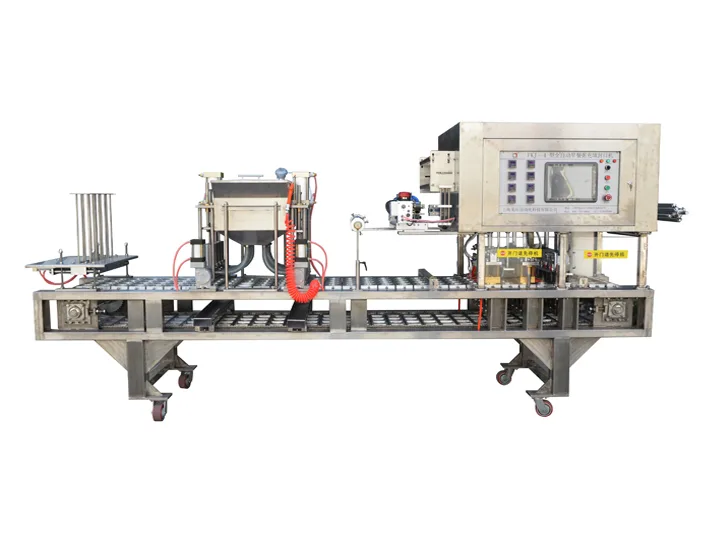

Product Overview

Longxiang Automatic Filling and Sealing Machine is tailor-made for the tofu products and soft food industry, catering to diverse boxed products such as lactone tofu, firm tofu, konjac tofu, duck blood tofu, braised delicacies, and prepared dishes. The machine supports dual process modes: fully automatic filling & sealing and standalone sealing, compatible with both dry and wet materials. With one-click switching between production plans, it helps enterprises reduce costs, enhance efficiency, and seamlessly step into the era of intelligent manufacturing.

Core Advantages

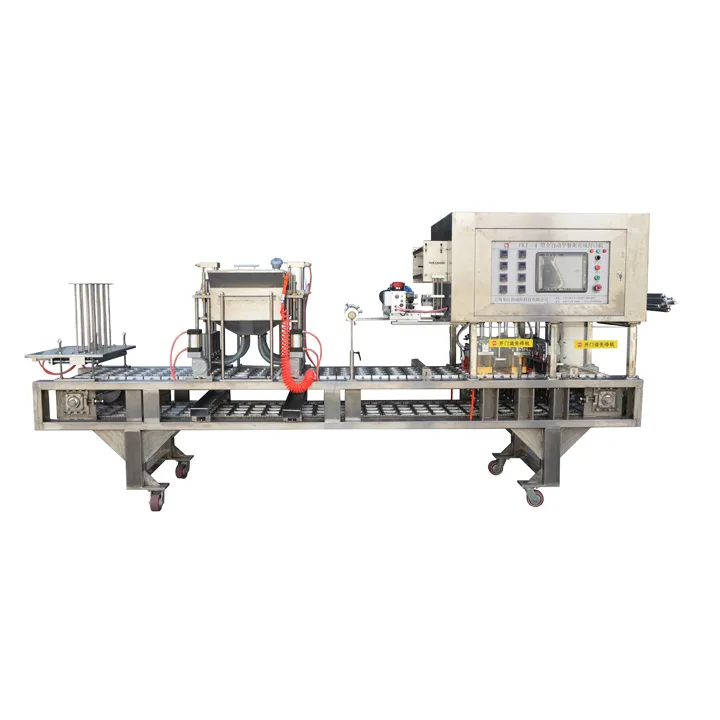

End-to-End Automation, Labor-Saving

Integrates automatic water injection → precise filling → film sealing → cutting → waste film recycling → online coding → finished product output in a fully automated process. Eliminates manual intervention, reduces 3-5 workers per machine, and boosts overall efficiency by 60%.

Dual-process flexibility: Supports liquid-injection filling (e.g., tofu hydration) or standalone sealing (e.g., fresh-lock packaging for prepared dishes), adapting to diverse production scenarios.

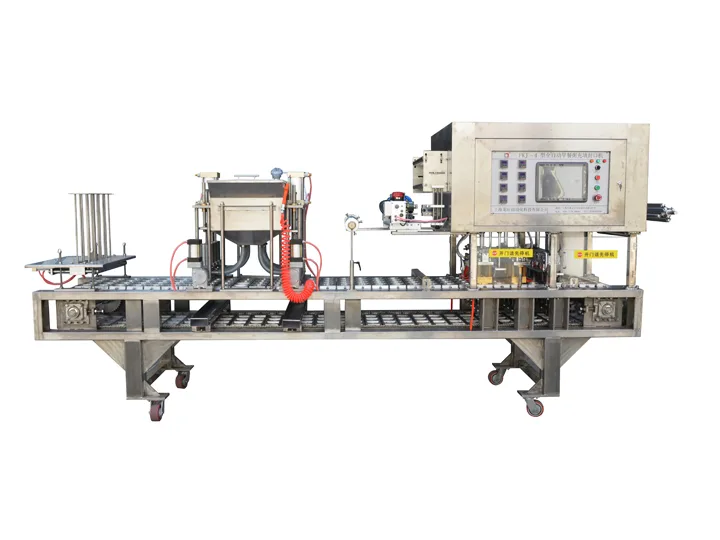

High Efficiency, Multi-Model Coverage

Standard configurations include 2-outlet, 3-outlet, and 4-outlet multi-station models, with a single machine capacity of up to 4,000 boxes/hour. Enables 24/7 continuous production to meet bulk order demands.

Modular structure design shortens model-changeover time to 15 minutes, ensuring rapid response to multi-category orders.

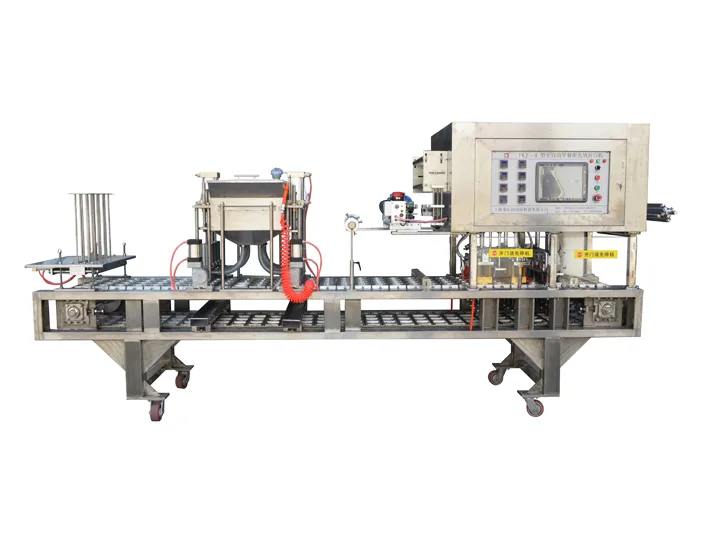

Precision Customization, Broad Compatibility

Customizable box types: Adapts to square, round, or irregular-shaped boxes, with capacities ranging from 150ml to 1000ml. Compatible with PE, PP, and composite aluminum films.

Intelligent filling system: Optional peristaltic or piston pumps handle fragile materials like tofu and duck blood, achieving filling accuracy ≤±1.5% and sealing success rate ≥99.9%.

Technical Highlights

Smart Visual Alignment: Utilizes CCD image positioning technology to track film patterns in real time, automatically correct offsets, and ensure packaging aesthetics and brand consistency.

Eco-Friendly Design: Waste film auto-winding system achieves over 95% recycling rate, minimizing material waste. Low-power motors and intelligent temperature-controlled sealing reduce energy consumption by 30%.

Compliance & Traceability: Built-in high-resolution coder prints production dates, batch numbers, QR codes, and more directly on sealed films, complying with food safety traceability standards.

Applications

Beyond tofu products, the machine is widely suitable for automated packaging of konjac blocks, duck blood cubes, braised ready-to-eat foods, instant salads, sauce packets, hot pot ingredients, and pre-washed vegetables, meeting diverse requirements for ambient, refrigerated, or modified atmosphere packaging.

Customization Services

Capacity customization (2,000–6,000 boxes/hour), functional add-ons (weight detection, vacuum nitrogen flushing, X-ray foreign object detection), and production line integration (seamless connection with upstream sterilization and cooling equipment).

Complimentary box-type compatibility testing and process validation to ensure perfect machine-product alignment.

Longxiang Intelligent Manufacturing – Empowering Traditional Foods to Embrace Industry 4.0!

Contact us now for a free trial machine and industry-specific solutions!