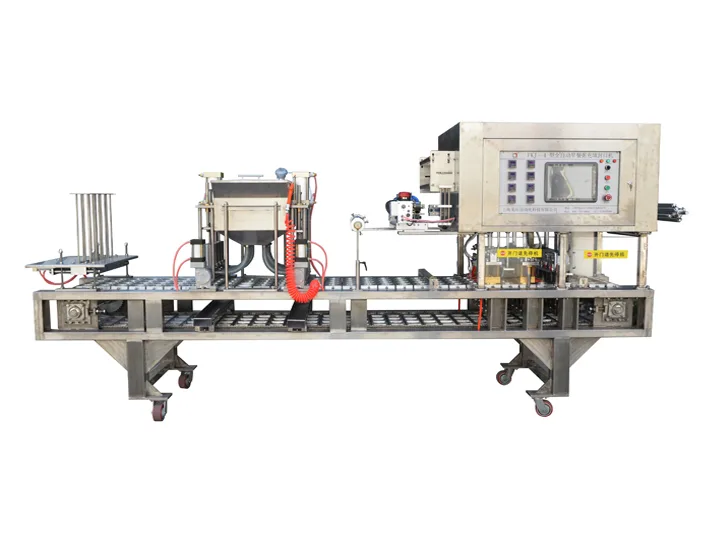

- Equipment Features

Aseptic Process Design

Fully automated closed system:

Cup feeding → Pressing → Low-temperature filling → Sealing → Misalignment correction (Photoelectric tracking/Pattern alignment) → Film cutting → Waste film recycling → Cup ejection

Minimized human contact compliant with dairy hygiene standards

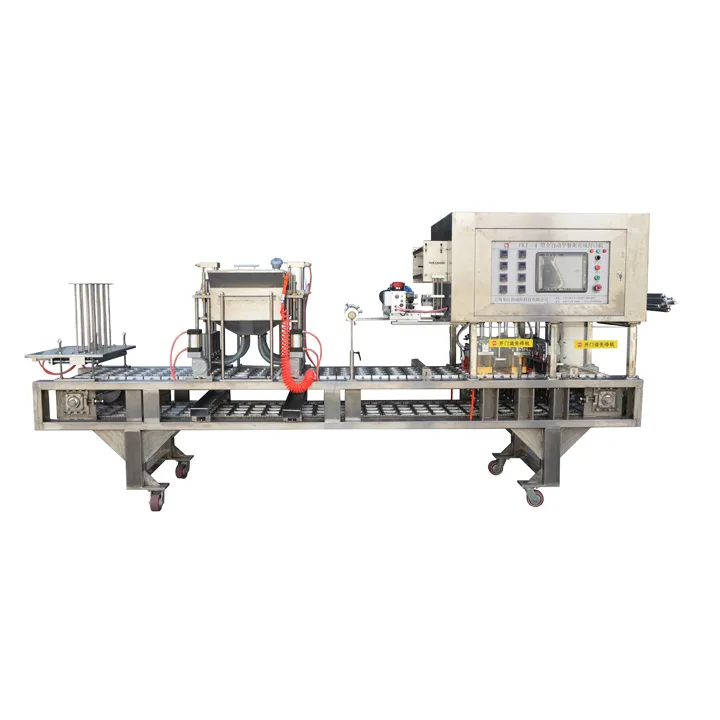

Yogurt-Specific Filling System

Servo-driven filling pumps handle high-viscosity yogurts (Greek-style, stirred)

Bubble-free & drip-free filling

Optional nitrogen flushing extends shelf life

Low-Temperature Sealing

Precision temperature control (80-150°C adjustable)

Protects probiotic viability

Ensures wrinkle-free seals

Intelligent Operation

Japanese/German core components (Omron sensors, Mitsubishi PLC, Festo cylinders)

<0.3% failure rate supports 24/7 production

Touchscreen HMI for real-time monitoring

- Core Functions

Applications

Dairy: Set yogurt, stirred yogurt, Greek-style, probiotic drinks, cheese pudding

Extended: Jelly, ice cream, juices, sauces, chocolate spreads (semi-fluid foods)

Key Processes

✅ Hygienic Filling

316L stainless steel contact surfaces

CIP/SIP compatible

✅ Precision Dosing

±0.5% filling accuracy

Adapts to 50-1000ml cups (round/square/special-shape)

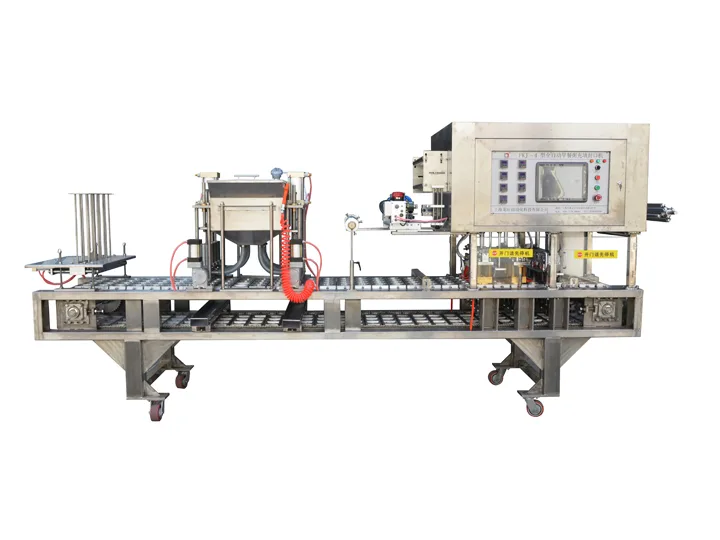

✅ Intelligent Alignment

Photoelectric date/logo positioning

- Product Advantages

🔬 Sanitary Compliance

GMP/HACCP certified

Cleanroom interface optional

⚡ Efficiency & Economy

30% energy savings (servo system)

≥95% film recycling rate

<30 min format changeover

🛠️ Customization Options

In-line weight check/rejection

Laser date/batch coding

Aseptic filling module (ambient yogurt)

- Target Applications

Dairy Plants: Chilled yogurt, premium probiotics, functional dairy lines

Foodservice: Central kitchen portioning, custom dessert cups

Emerging Markets: Plant-based yogurts (soy/coconut), stage-specific nutritional products

- Summary

Engineered for yogurt excellence, this machine delivers:

Aseptic processing

Probiotic protection

Precision filling

Solving critical challenges in hygiene control, seal integrity, and production efficiency. Empowers manufacturers to achieve large-scale, premium-quality dairy production meeting evolving consumer demands.