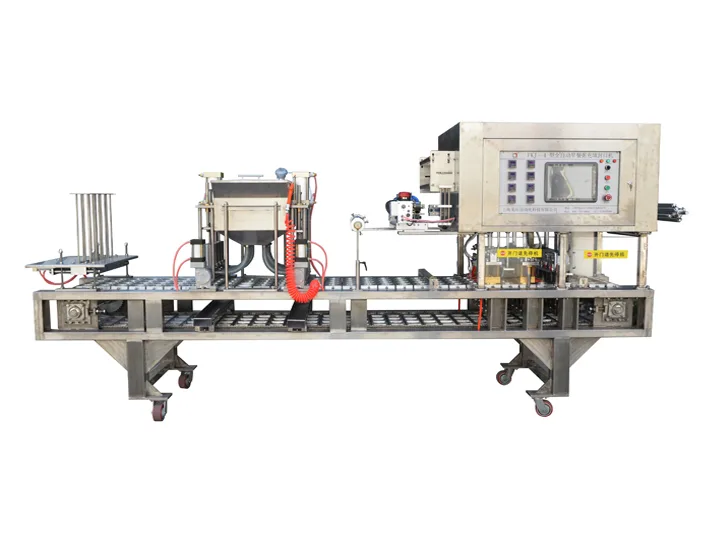

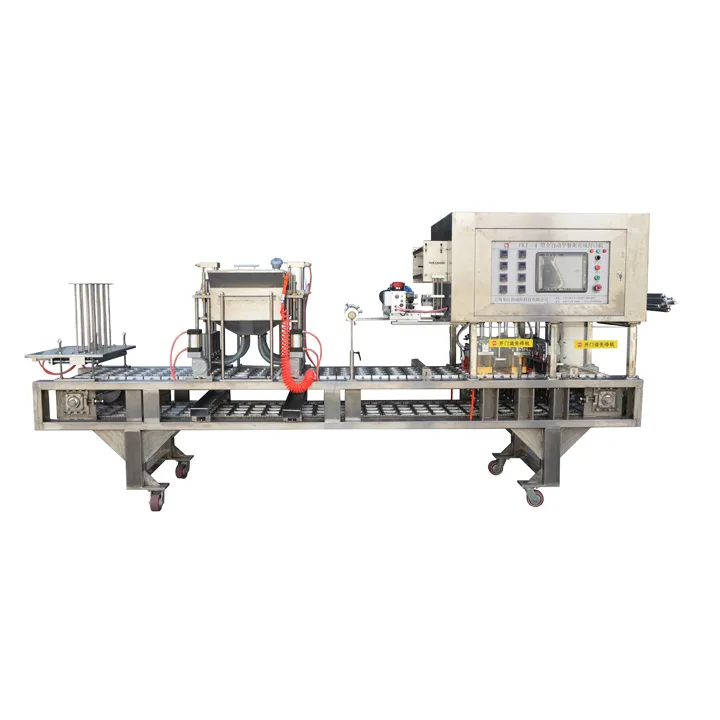

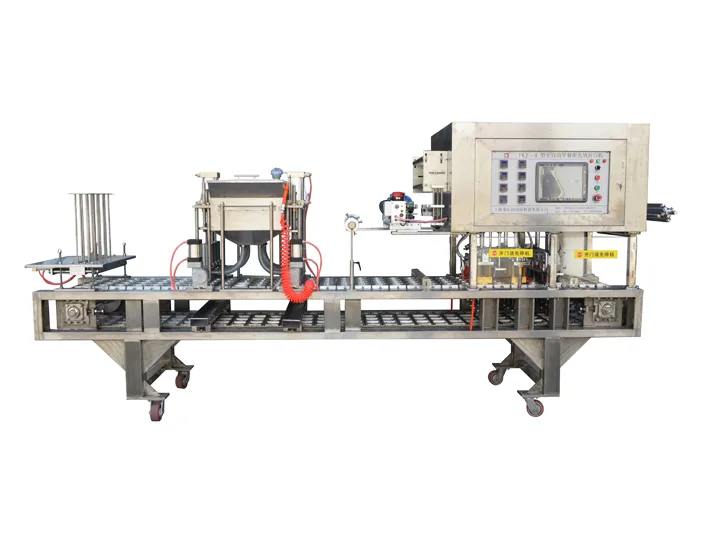

This machine is a high-efficiency, stable, and easy-to-operate full-automatic liquid beverage filling and sealing equipment. Designed to meet the modern food and beverage production requirements for high-speed, precision, and hygiene, it is widely applicable to the automated packaging of various liquid and semi-fluid foods.

Core Advantages and Equipment Features

Full-Process Automation

Integrates eight processes: cup feeding, cup pressing, filling, sealing, deviation correction (photoelectric tracking/pattern correction), cutting, waste film recycling, and cup discharging.

Achieves continuous unmanned operation from empty cup input to finished product output, significantly improving production efficiency and reducing labor costs.

Innovative Structural Design

Overhead transmission and control system: The core transmission components and electrical control system are installed on the upper part of the equipment.

Convenient operation: This design facilitates daily operation, parameter setting, status monitoring, and maintenance for operators.

Stable performance: Optimized structural layout ensures high stability and reliability during operation.

Simple maintenance: Key components are easily accessible, simplifying maintenance and troubleshooting.

Precision and Reliability

Precise filling volume: Adopts advanced metering technology to ensure highly accurate filling volume, meeting strict process standards.

Excellent sealing quality: The stable sealing system ensures firm sealing and a smooth, beautiful appearance.

High-precision deviation correction: Equipped with a photoelectric tracking system to achieve precise pattern correction and positioning of packaging films, ensuring uniform sealing patterns and enhancing product appearance quality.

Superior Quality of Core Components

Key electrical and pneumatic components (e.g., PLC, sensors, solenoid valves, cylinders, etc.) are selected from internationally renowned brands in Japan, Germany, etc.

Quality guarantee: Ensures durability, stability, and long-term operation precision from the source, effectively reducing failure rates.

Modularity and Expandability

Optional coding machine: Can flexibly integrate online coding/inkjet equipment as per customer needs to print production dates, batch numbers, shelf life, etc., directly on cup lids or bodies.

Wide Application Functions

This machine features excellent compatibility and flexibility, suitable for various containers (e.g., plastic cups, paper cups) and contents, especially proficient in handling:

Liquid beverages: Fruit juice, tea drinks, functional drinks, mineral water, etc.

Dairy products: Yogurt, lactic acid bacteria drinks, fresh milk pudding, etc.

Desserts and cold drinks: Jelly, pudding, ice cream, smoothies, etc.

Sauces and seasonings: Salad dressing, ketchup, sauce, jam, etc.

Other fluid/semi-fluid foods: Chocolate sauce, honey, syrup, etc.

This full-automatic liquid beverage filling and sealing machine is an ideal choice for modern food and beverage production lines. Its high automation, precision, reliability, convenient operation and maintenance, and high-quality core components ensure efficient, stable, and high-quality production output. Whether enterprises aim to improve productivity, optimize costs, or upgrade quality, they can achieve significant benefits from this machine. Its wide applicability also meets the production needs of diversified products.

(Optional addition: For specific technical parameters such as production speed, applicable cup size range, power, etc., please provide further requirements.)