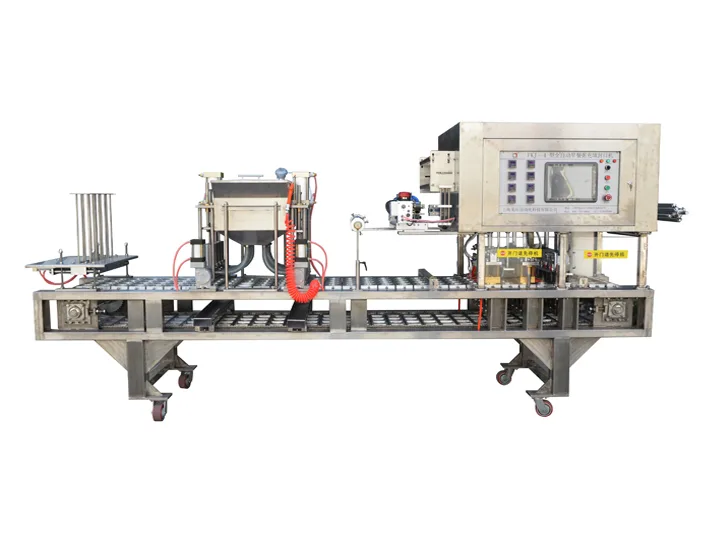

Product Overview

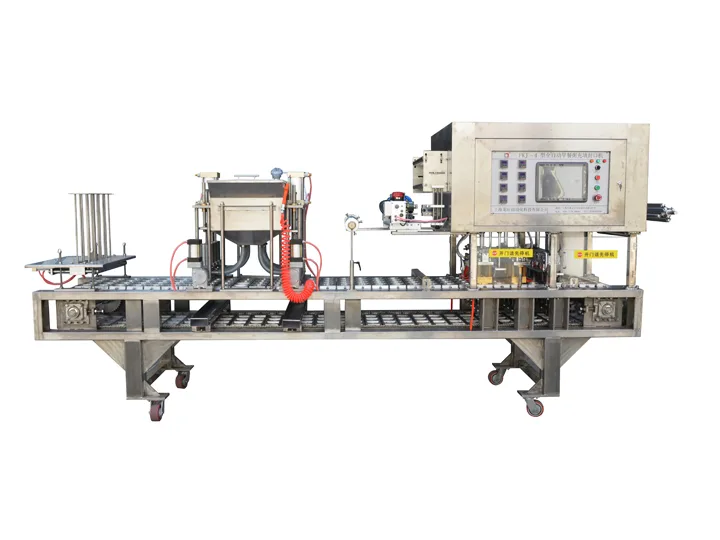

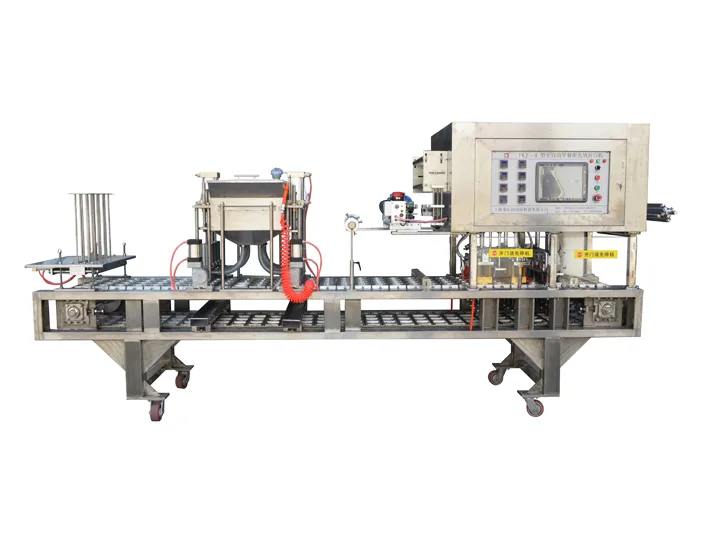

This filling production line is designed for the fluid and semi-solid food industry, integrating filling, sealing, conveying, and basket collection to achieve full-process automation from raw materials to finished products. The production line adopts a modular layout and is suitable for a variety of containers (boxed, bottled, cupped) and product types (sauces, liquid foods, soft products), significantly improving production capacity stability and operation safety, and helping enterprises build standardized, unmanned smart factories.

Core equipment composition

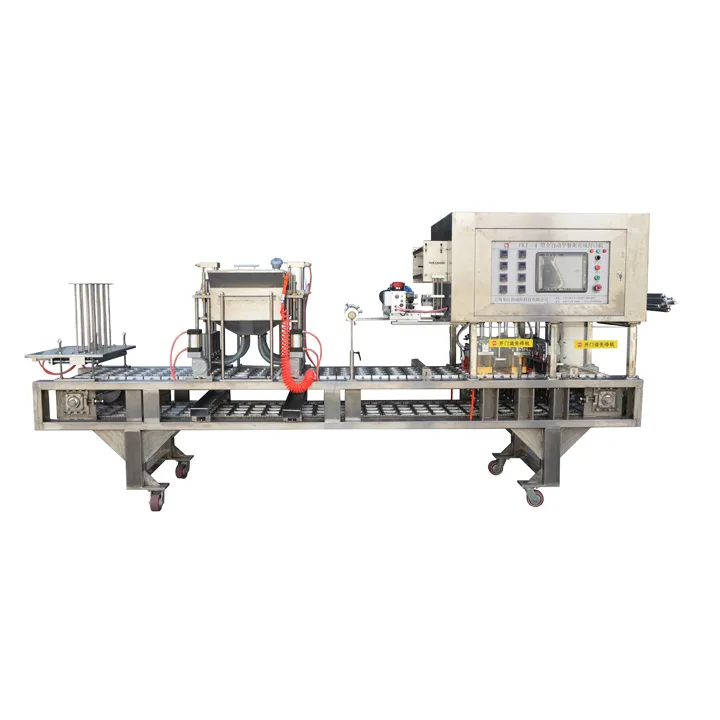

Fully automatic filling and sealing machine

Precise quantitative filling, supporting liquid, paste, semi-solid materials (such as jam, yogurt, tofu, pre-prepared vegetable soup), filling error ≤±1%.

Heat sealing/ultrasonic sealing optional, compatible with PE, PP, aluminum foil and other sealing materials, sealing qualified rate ≥99.5%.

Climbing conveyor belt

Seamlessly connect upstream and downstream processes, adjustable inclination angle (15°-30°), non-slip and wear-resistant conveyor belt ensures smooth transition of products to avoid spillage or deformation.

Frequency conversion speed control, matching different production capacity rhythms, maximum load 50kg/㎡, supporting 24-hour continuous operation.

Basket loading platform

Automatic basket sorting, positioning, stacking, intelligent counting system accurately matches basket capacity, automatic warning when full basket.

Customizable multi-layer stacking (3-5 layers) or single-layer flat paving mode, suitable for a variety of carriers such as plastic baskets and metal baskets.

Basket unloading platform

Automatic basket unloading by robotic arms or pneumatic grippers, seamless docking with AGV/forklifts, realizing unmanned transportation of finished products.

Equipped with a photoelectric detection system, empty baskets automatically return to the basket loading station to form a closed loop.

Core advantages

Full chain automation: filling → sealing → conveying → loading → unloading, all unmanned, saving 6-8 workers and increasing efficiency by 70%.

Flexible expansion: supports adding or removing equipment modules (such as adding labeling machines and visual inspection instruments), and quickly adapts to new products or process upgrades.

Stable and durable: food-grade stainless steel body, key components use imported accessories from Japan/Germany, and the failure rate is less than 0.5%.

Intelligent management and control: The central control system monitors production data (capacity, fault points, energy consumption) in real time, and supports remote operation and maintenance in the cloud.

Applicable fields:

Large-scale production of foods such as jam, condiments, liquid milk, boxed tofu, konjac products, ready-to-eat desserts, hot pot base, pre-prepared vegetable soup, etc., and can also be expanded to fluid packaging in the daily chemical and pharmaceutical industries.

Technical highlight

Precise anti-overflow filling: peristaltic pump/piston pump adapts to viscosity changes, and is equipped with liquid level photoelectric sensor to prevent dripping.

Energy saving and consumption reduction: servo motor drive, energy consumption is reduced by 40% compared with traditional equipment; the automatic recovery rate of waste film/waste material reaches 98%.

Quick changeover: mold and parameter pre-storage function, production change time ≤ 20 minutes, supporting small batch multi-category flexible production.

Service Support

Provide one-stop service for production line planning, equipment selection, online debugging, and technical training.

Customized development of container specifications, production capacity (2000-10000 pieces/hour), and automation level (semi-automatic/fully automatic/intelligent factory integration).

From single machine to production line, empowering efficient and intelligent manufacturing for a new future!

Consult now to get a free production line design plan and quotation list!