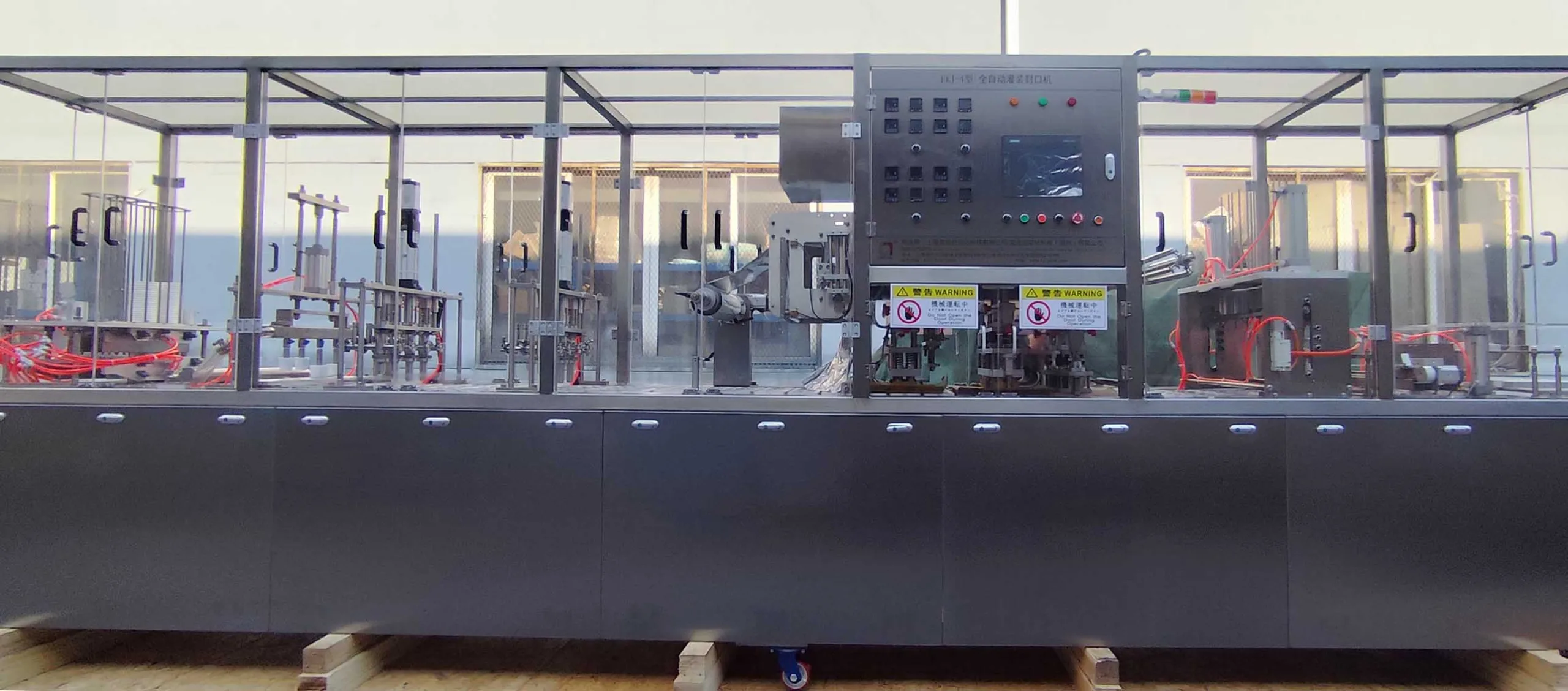

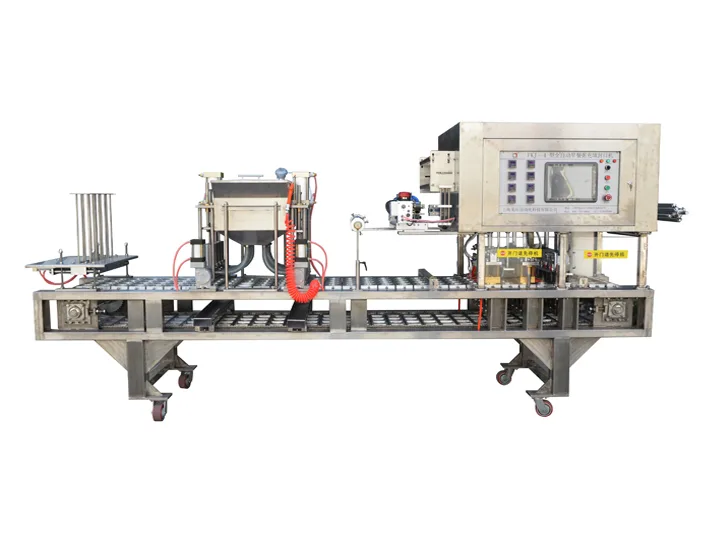

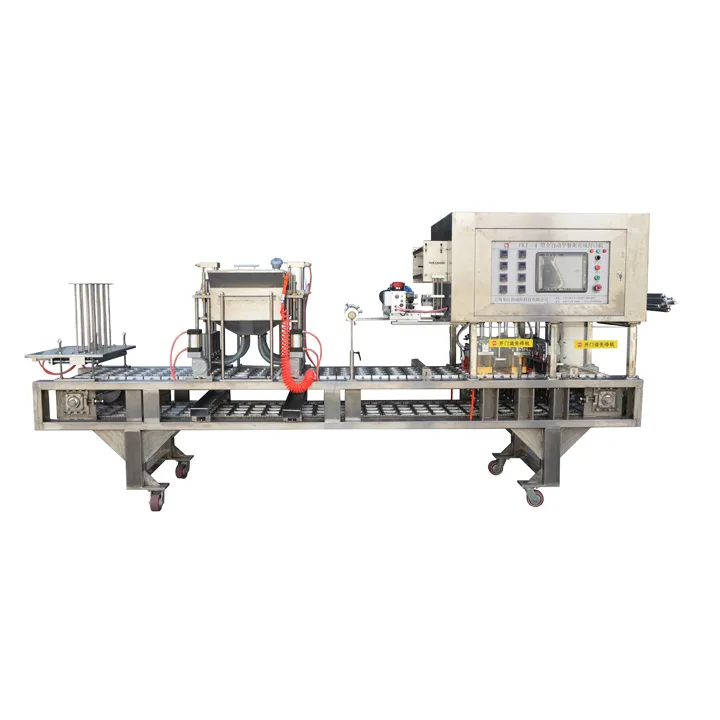

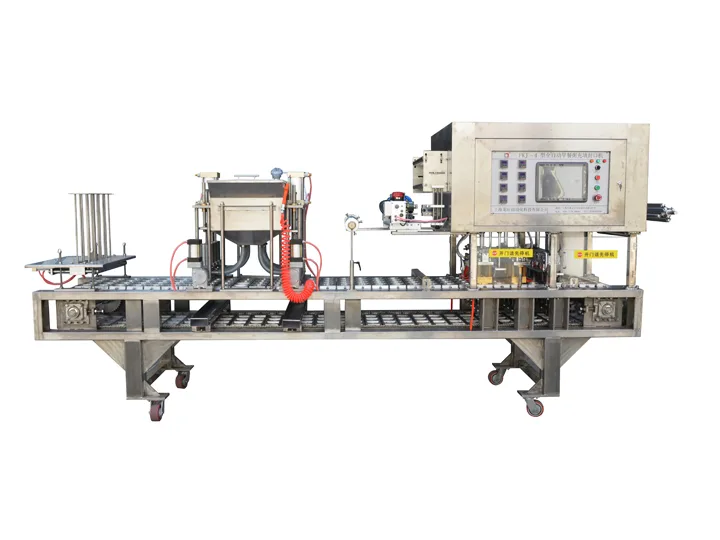

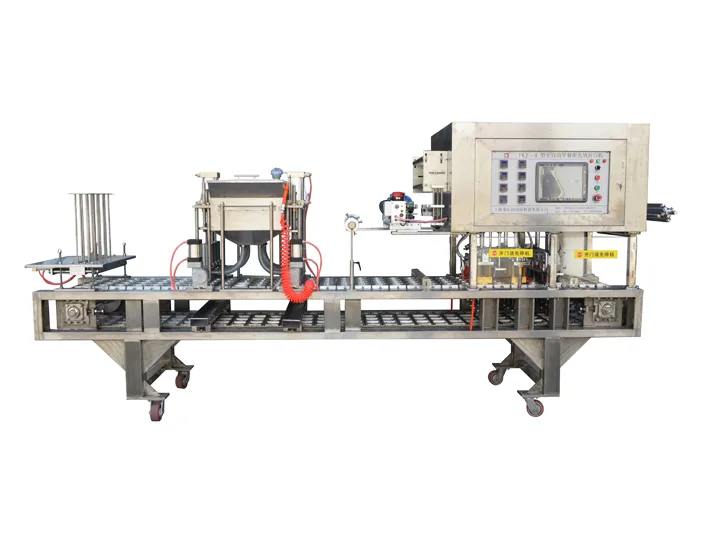

This fully automatic filling and sealing machine is specifically engineered for ice cream, dairy products, beverages, and various fluid foods. Integrating intelligence, high efficiency, and versatility, its modular design covers the entire automated process from cup feeding, precision filling, sealing, to finished product output. Empowers enterprises to achieve standardized, large-scale production while significantly enhancing packaging efficiency and product quality.

Core Advantages

End-to-End Automation, Precision & Reliability

Seamlessly executes processes:

Cup feeding → Cup pressing & positioning → Quantitative filling → Heat sealing → Misalignment correction (Photoelectric tracking/Pattern alignment) → Film cutting → Waste film recycling → Cup ejection

Minimizes human intervention and eliminates contamination risks

High-precision servo systems and pneumatic components (Japanese/German core parts) ensure leak-proof sealing and ±1% filling accuracy

Adapts to fluids of varying viscosities

User-Centric Design, Easy Maintenance

Overhead structural layout: Transmission mechanisms and electrical components concentrated in upper section

Ergonomic interface placement enables effortless daily maintenance and cleaning

Modular components support quick disassembly

Intelligent fault diagnostics minimize downtime

Flexible Scalability, Wide Compatibility

Optional inline coding device for real-time printing of production dates/batch codes (supports food traceability)

Customizable cup molds (round/square/special-shaped) and adjustable capacities (50ml-500ml)

Compatible with PE/PP/aluminum foil sealing films for refrigerated or ambient storage

Applicable Fields

Beyond ice cream, seamlessly packages:

Jelly | Yogurt | Juice | Salad Dressing | Chocolate Sauce | Condiments | RTD Beverages

One machine for diverse fluid/semi-fluid foods – empowers rapid response to market demands

Technical Highlights

Intelligent Alignment System: High-sensitivity photoelectric sensors auto-correct film pattern deviations

Energy Saving: Automatic waste film recycling reduces material loss

Durability: Industrial-grade stainless steel frame with food-contact materials

Compliance: Meets HACCP/GMP certification standards

Customization Services

Provides solutions from standalone units to complete production lines:

Customizable output (2,000-12,000 cups/hour)

Functional expansions & process upgrades

Empower your production line!

Enhance packaging intelligence while boosting production efficiency!

Contact us now for customized configuration plans and technical demos!