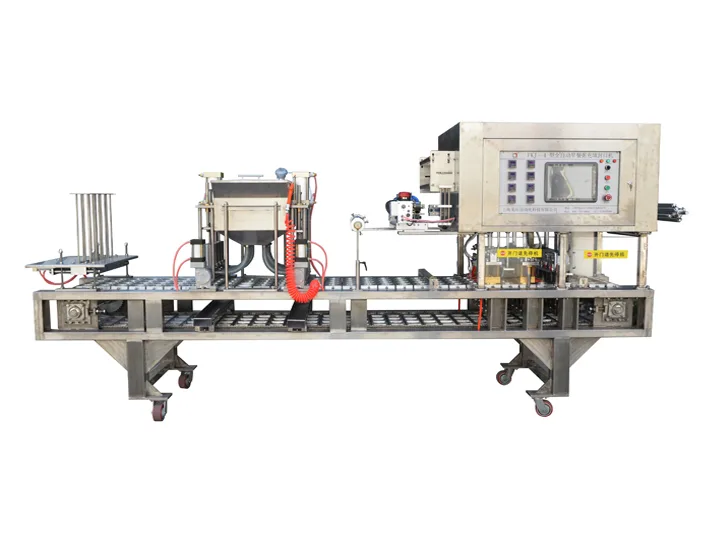

Equipment Features

Fully automated process

Integrated cup feeding, cup pressing, filling, sealing, deviation correction (photoelectric tracking/pattern correction), shearing, waste film recovery, cup removal and other processes, without manual intervention.

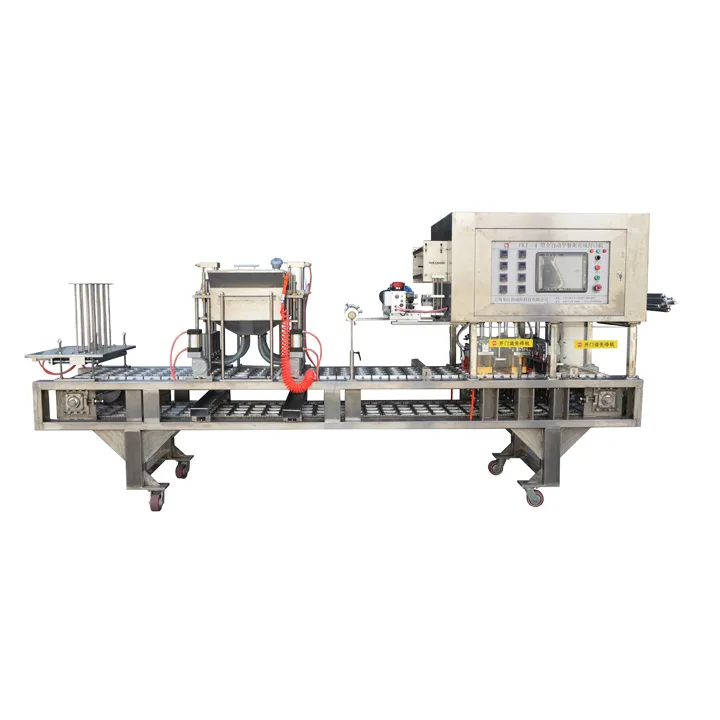

Innovative structural design

Transmission parts and electrical components are centrally installed on the upper part of the equipment, with a friendly operating interface and convenient maintenance.

High precision and stability

The use of electrical and pneumatic components imported from Japan and Germany (such as SMC pneumatic parts, Mitsubishi PLC, etc.) ensures accurate gas volume and stable operation.

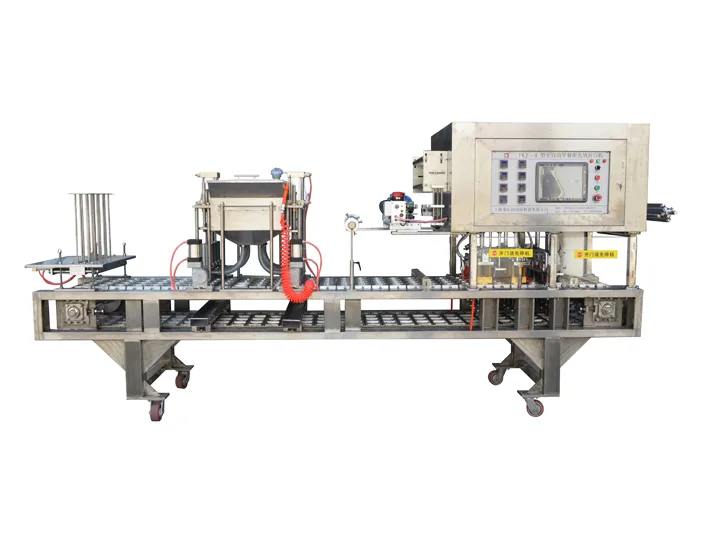

Flexible scalability

Optional coding machine to meet product date, batch number and other identification requirements.

Equipment function

Applicable products: jelly, yogurt, ice cream, juice, condiments, chocolate, salad and other fluid or semi-fluid foods.

Core technology: precise filling, high-speed sealing, automatic deviation correction (to ensure packaging pattern alignment), waste film recycling, environmental protection and energy saving.

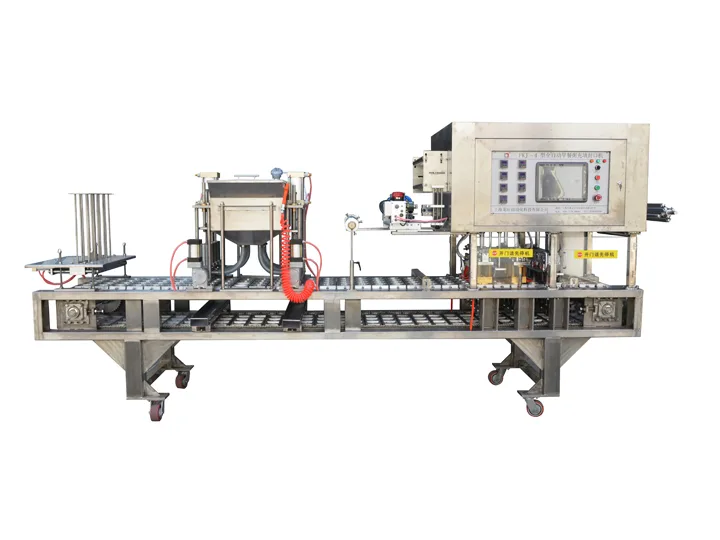

Product advantages

Efficient and energy-saving: Full automation reduces labor costs, and the waste film recycling system reduces material waste.

Easy maintenance: Modular design, key components are easy to disassemble and clean.

High compatibility: Adapt to a variety of cup types and materials (PP/PS/aluminum film, etc.), fast switching.

Quality assurance: Imported core components extend the life of the equipment, and the sealing seal meets food grade standards.

Applicable industries

Dairy processing, snack food manufacturing, condiment production, cold drink industry, catering supply chain, etc.

With intelligent design, stable and efficient performance and flexible expansion capabilities, this equipment has become an ideal solution for food filling and sealing, helping enterprises to improve production capacity and product consistency and meet diversified production needs.