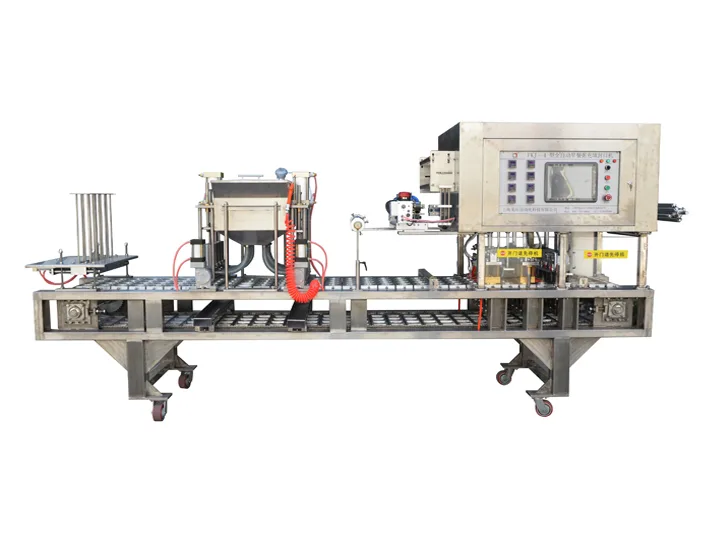

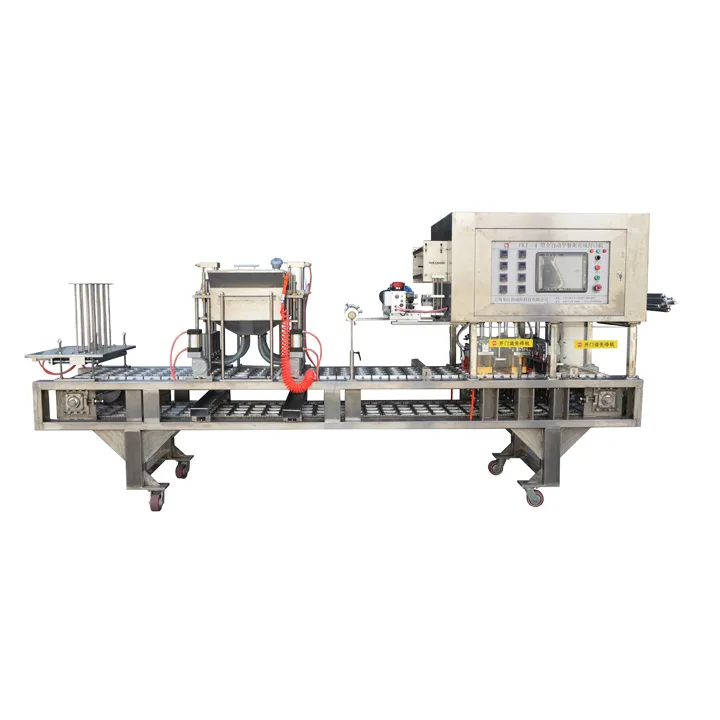

Equipment Features

Full-process aseptic design

Integrated cup feeding, cup pressing, low-temperature precision filling, sealing, deviation correction (photoelectric tracking/pattern correction), shearing, waste film recovery, and cup removal fully automated process. The closed structure reduces manual contact and meets the hygiene standards of dairy products.

Yogurt-specific filling system

The servo motor drives the filling pump, which is suitable for high-viscosity yogurt (such as Greek yogurt and stirred yogurt), and the filling is bubble-free and drip-free;

Optional nitrogen replacement function can be used to extend the shelf life of yogurt.

Low-temperature sealing protects active ingredients

Precise sealing temperature control (adjustable from 80-150℃) prevents high temperature from destroying the activity of yogurt probiotics and ensures a smooth seal without wrinkles.

Intelligence and stability

The core electrical and pneumatic components are imported from Japan (Omron sensors, Mitsubishi PLC) and Germany (Festo cylinders), with low failure rates and support for 24-hour continuous production;

The human-machine interaction interface (touch screen) monitors parameters in real time and is easy to operate.

Equipment Function

Core Application:

Dairy products: set yogurt, stirred yogurt, Greek yogurt, probiotic drinks, cheese pudding, etc.;

Extended compatibility: semi-fluid foods such as jelly, ice cream, juice, sauce, chocolate sauce, etc.

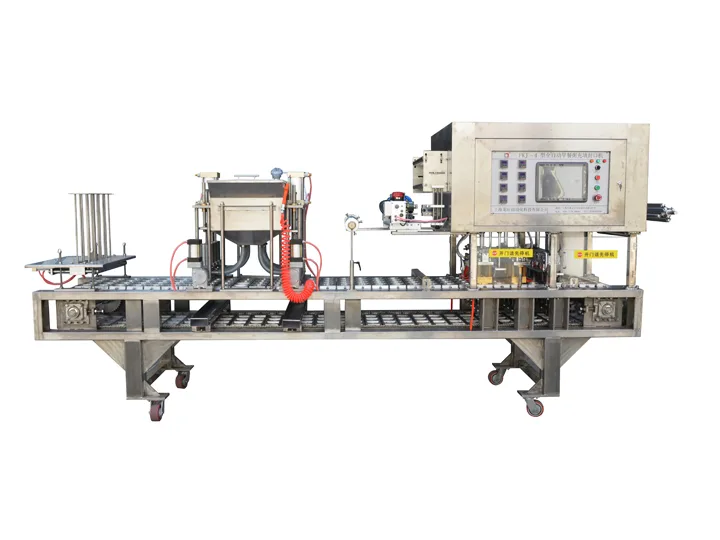

Core Technology:

Highly hygienic filling: hopper and pipeline are made of 316L stainless steel, supporting CIP/SIP online cleaning;

Precise capacity control: filling accuracy ±0.5%, suitable for a variety of cup types (round cup, square cup, special-shaped cup) from 50 to 1000mL;

Intelligent deviation correction: photoelectric system automatically aligns the date/logo on the packaging film to improve the appearance of the product.

Product Advantages

Sanitary safety guarantee

The whole machine complies with GMP/HACCP standards, there is no sanitary dead corner in the contact parts, and a clean room adapter interface can be optionally equipped.

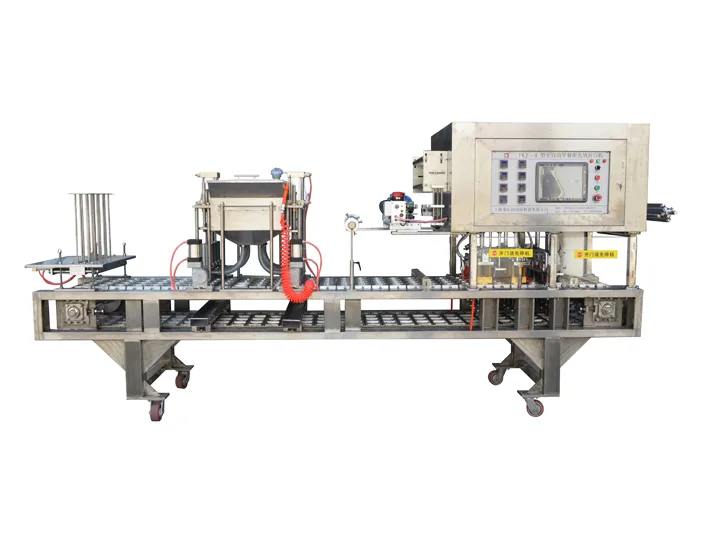

High efficiency and energy saving

Servo system saves 30% energy, waste film recovery rate ≥95%, reducing packaging material costs;

Quick mold change design (cup type switching can be completed within 30 minutes).

Customized service

Optional functions:

Online weighing detection and rejection system;

Date/batch laser coding;

Aseptic filling module (suitable for room temperature yogurt).

Applicable scenarios

Dairy processing plants: low-temperature yogurt, high-end probiotic products, functional dairy production lines;

Chain restaurants: central kitchen yogurt packaging, customized small cup desserts;

Emerging markets: plant-based yogurt (soy milk, coconut milk), children’s segmented nutritional yogurt.

Summary

This equipment is specially developed for the yogurt industry. With aseptic design, active ingredient protection, and high-precision filling as its core competitiveness, it solves the pain points of hygiene control, sealing, and filling efficiency in yogurt production, helping enterprises to achieve large-scale production of high-quality dairy products and meet the needs of consumer upgrades.