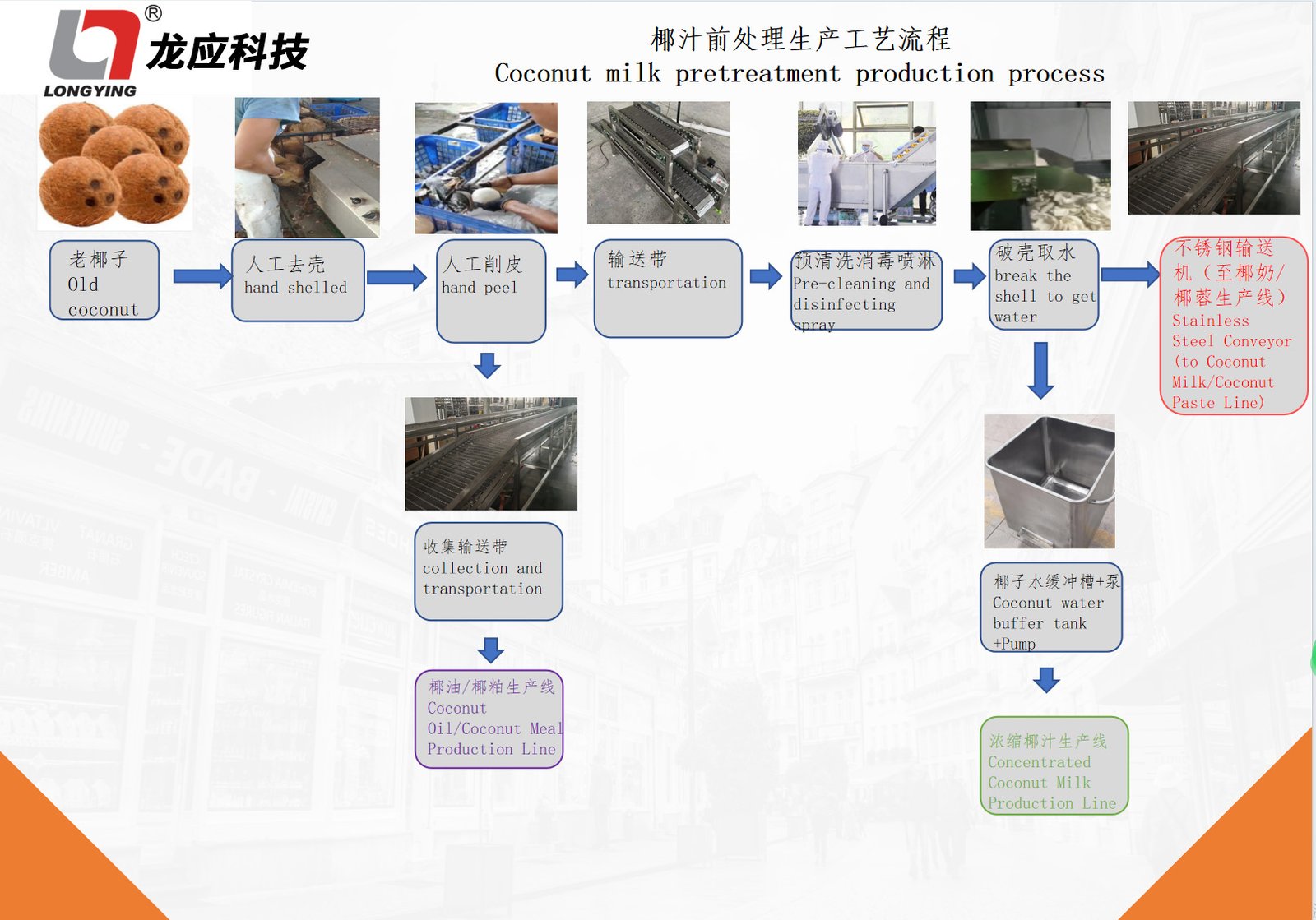

Overview of the production line

The coconut juice production line is an automated production line that integrates coconut cleaning, shelling, juice extraction, blending, sterilization, and filling. The production line uses advanced mechanical equipment and process technology to efficiently and stably produce high-quality coconut juice drinks.

Advantages of the production line

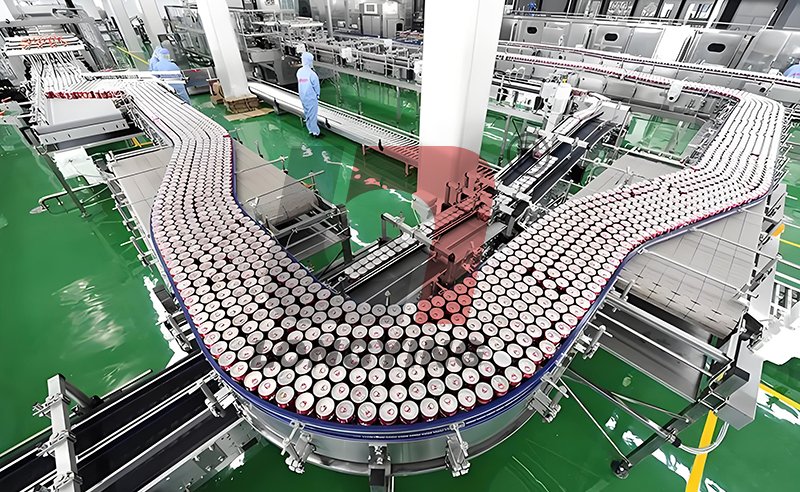

- Efficient automation: The entire production line uses an automated control system to achieve a continuous process from raw material processing to finished product packaging, greatly improving production efficiency.

- Stable quality: Through precise metering and mixing systems, as well as advanced pulping and emulsification technology, the taste and quality of coconut juice are ensured to be stable.

- Safety and sanitation: The production line uses high-temperature sterilization to effectively kill bacteria and ensure the safety of the product. At the same time, the equipment is made of food-grade stainless steel, which is easy to clean and maintain, ensuring the hygiene of the production environment.

- Energy saving and environmental protection: The production line focuses on energy saving and environmental protection in design, and uses energy-saving equipment and processes to reduce energy consumption and environmental pollution.

Equipment composition

The coconut juice production line is mainly composed of the following equipment:

- Coconut shelling machine: responsible for breaking the cleaned coconut shells to facilitate the extraction of coconut water and coconut meat.

- Coconut meat drying machine: drying the scraped coconut meat to make dry shreds in preparation for subsequent grinding.

- Grinding equipment: using colloid mill or ultra-fine grinding technology, the dried coconut shreds are mixed with hot water and ground into fine coconut juice.

- Mixing equipment: including sandwich pots, liquid mixing tanks, etc., responsible for mixing coconut milk, coconut water, concentrated syrup, citric acid seasoning, salt, emulsifiers and other ingredients according to the formula ratio, and stirring and heating.

- Emulsification and homogenization equipment: emulsify the prepared coconut beverage to make it more uniform and stable.

- Sterilization equipment: perform (UHT) high-temperature sterilization on the homogenized coconut beverage to ensure the safety of the product.

- Automatic filling machine sealing equipment: fill the sterilized coconut beverage into bags, quilts, bottles or cans, and seal it with a sealing machine or sterilize it with a secondary high-temperature sterilizer to prevent leakage and contamination.

Application scenarios

The coconut juice production line is suitable for coconut juice production enterprises of various sizes, including large beverage factories, small and medium-sized food processing factories, and entrepreneurial beverage stores. Through this production line, enterprises can flexibly adjust production scale and product types to meet the diversified needs of the market.