Longying Juice Beverage Production Line — Crafting Freshness, Filling the Future

Dedicated to providing global beverage enterprises with turnkey solutions from raw materials to finished products. Centered on aseptic manufacturing technology, we deliver high-efficiency, stable production lines perfectly adapted for cup-packed/pouch-packed beverages.

Avantages principaux :

Aseptic Cold Filling: UHT instant sterilization (105-125°C, 3-15s) + aseptic filling reduces thermal damage by 60%, locking in fresh fruit flavor and nutrients—achieving a “fresh-on-tongue sensation” for cup/pouch products.

Flexible Packaging: Modular design seamlessly adapts to plastic cups and stand-up pouches. ±0.5% filling accuracy and 99.98% sealing integrity effortlessly handle fruit pulp and particles.

Smart Control Hub: IoT central control synchronizes key modules, boosting efficiency by 40% while reducing energy consumption by 15%. Flexible daily output: 5-80 tonnes.

End-to-End Empowerment: Full support from planning, customization to training. Compliant with FDA/ISO22000 standards. Ready solutions for cup-packed, pouch-packed, and NFC beverages empower rapid market expansion.

Choosing Longying means choosing a juice manufacturing future of “controllable freshness, visible efficiency, and reducible costs”!

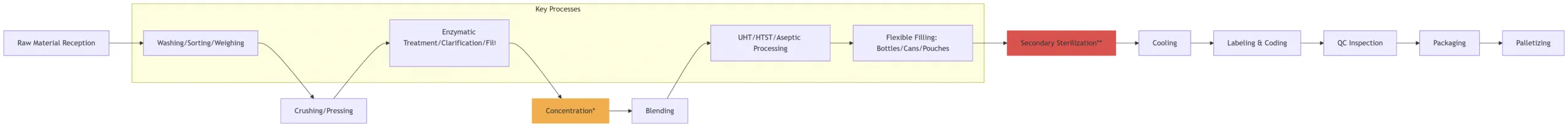

High-efficiency washing, sorting, crushing, pressing/extraction technologies (fruit-specific solutions)

Enzymatic treatment, clarification, filtration (ultrafiltration/microfiltration) processes & equipment

Optional concentration technologies: Thermal, freeze, and membrane concentration

Fully automated batching system with high precision and batch consistency

Key Highlight: Advanced sterilization processes (UHT, HTST pasteurization, aseptic cold filling) featuring precise temperature control, low thermal load, and maximum flavor/nutrient retention

Core Advantage: Aseptic filling technologies (isolator/RABS systems) ensuring sterile environments

High-speed, high-precision filling valves adaptable to various packaging (bottles, cans, cartons, pouches)

Automated capping/sealing technologies (screw-capping, press-on, sealing, labeling) with reliable hermeticity

Centralized control (PLC/SCADA) with real-time monitoring, data logging, and remote diagnostics

Precise control and alarming for critical parameters (temperature, pressure, flow, level, fill volume)

Recipe management and production data traceability

Customizable line configurations (capacity, fruit types, process routes, packaging formats)

Future-proof expandability and upgrade capabilities

Energy Efficiency & Sustainability:

Optimized design reducing water, electricity, and steam consumption

Efficient CIP/SIP cleaning systems minimizing water and chemical usage

Materials and processes meeting global environmental compliance standards

| 您的果汁生产是否面临这些挑战? Challenges in Your Juice Production? | 龙应果汁生产线,为您提供全方位解决方案! Longying's Integrated Solutions! |

|---|---|

| ⚠️ 生产效率低,无法满足市场需求 Low throughput, unable to meet demand | ✅ 高效集成设计 → 产能提升40%+,损耗降低25% Optimized integration → 40%+ higher yield, 25% less waste |

| ⚠️ 产品品质不稳定,损耗率高 Inconsistent quality, high defect rate | ✅ 先进无菌灌装技术 → 微生物合格率99.99% Aseptic filling → 99.99% microbiological pass rate |

| ⚠️ 设备老旧,维护成本高昂 Aging equipment, high maintenance costs | ✅ 智能控制系统 → 故障率↓30%,维护成本↓35% IoT control → 30% fewer failures, 35% lower maintenance |

| ⚠️ 缺乏灵活性,难以适应新品开发 Rigid systems hinder innovation | ✅ 模块化设计 → 3天内切换配方/包装类型 Modular design → Recipe/packaging change in 72hrs |

| ⚠️ 人工依赖度高,成本压力大 Labor-intensive operations | ✅ 全自动化产线 → 操作人员需求减少60% Full automation → 60% less labor required |

| ⚠️ 无菌标准难以达标 Struggling with aseptic compliance | ✅ ISO22000/FDA合规设计 → 通过率100% Built-in compliance → 100% certification success |

| Core Advantages | Value Proposition |

|---|---|

|

Proven Experience

X years dedicated to liquid food equipment manufacturing, with deep understanding of juice industry needs, providing reliable solutions for global clients

|

Reduces trial-and-error costs, ensures project success at first attempt |

|

Technological Leadership

Continuous R&D investment, mastery of core technologies (especially sterilization and aseptic filling), maintaining industry-leading position

|

Enhances product quality, extends shelf life |

|

Turnkey Solutions

End-to-end responsibility from design, manufacturing, installation, commissioning to training and after-sales service

|

Eliminates multi-party coordination, shortens project timeline |

|

Strict Quality Control

Complies with international standards including GMP, HACCP, and ISO

|

Meets global market access requirements, enhances brand reputation |

|

Global Service Network

Rapid-response localized/global technical support and spare parts supply

|

Maximizes equipment uptime, reduces production losses |

|

Customization Capability

Not just a standard equipment supplier, but a solution partner providing optimal configurations

|

Perfectly matches production requirements, maximizes efficiency |

|

Exceptional Value

Reliable equipment delivers long-term stable ROI, reduces overall operating costs

|

Faster return on investment, sustainable profitability |

Nous sommes prêts à mettre notre sagesse et nos compétences au service de la société et à devenir votre partenaire de confiance.