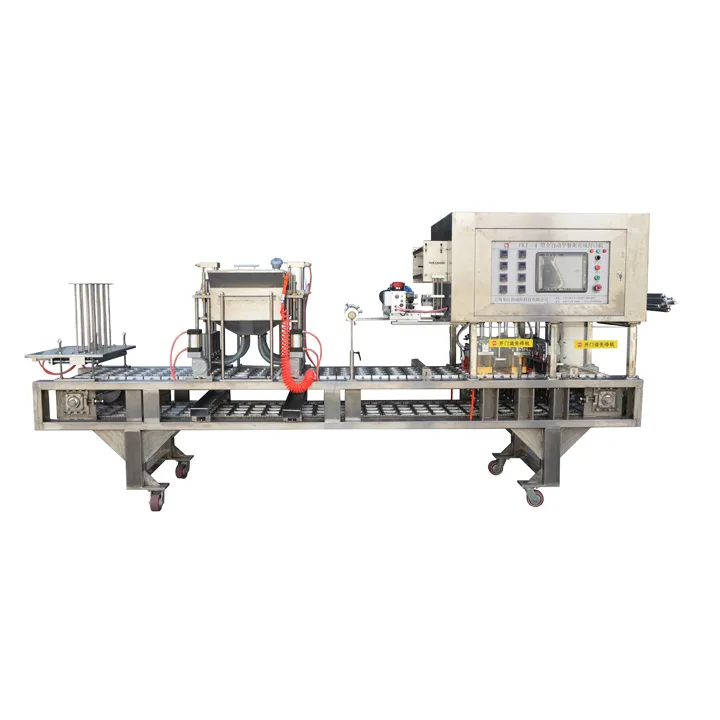

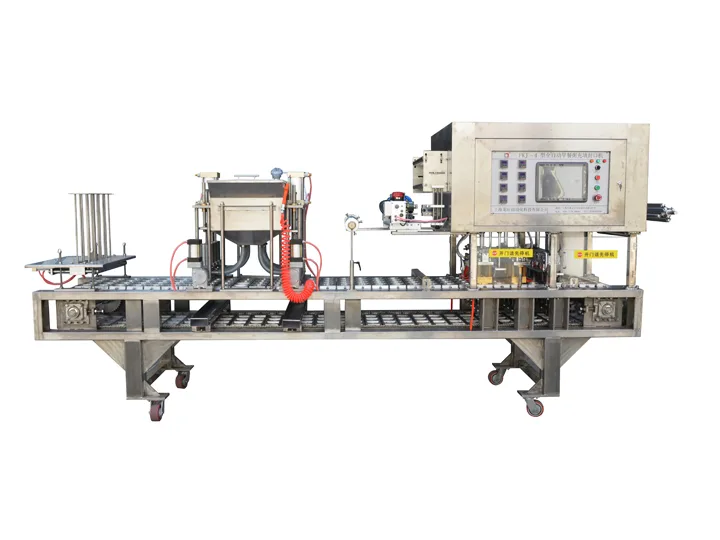

Equipment Features

Full process automation

Integrated cup feeding, cup pressing, high-precision filling, sealing, deviation correction (photoelectric tracking/pattern automatic correction), shearing, waste film recovery, cup removal and other processes to achieve unmanned operation, suitable for high-viscosity sauces (such as chili sauce, ketchup, salad dressing, etc.).

Specially designed for sauce optimization

Adopts anti-drip filling system to ensure high-viscosity sauce filling without residue; equipped with corrosion-resistant material hopper and pipeline, suitable for complex sauce formulas such as acidic and salty.

Stable and efficient

The transmission system and electrical components (Japan Mitsubishi PLC, Germany Festo pneumatic components) are centrally arranged on the upper part of the equipment, with intuitive operation interface, convenient maintenance, and high long-term operation stability.

Intelligent flexible production

Supports fast switching of multiple cup/bag types (round cup, square cup, self-supporting bag, etc.), optional coding machine, visual inspection system to meet diverse packaging needs.

Equipment Function

Core Application:

Sauces: chili sauce, ketchup, peanut butter, hot pot base, seasoning sauce, salad dressing, etc.;

Other foods: jelly, yogurt, ice cream, semi-fluid condiments, honey, chocolate sauce, etc.

Key Processes:

Precision filling: servo motor controls the filling volume, with an accuracy of ±1%, suitable for a variety of specifications from 30 to 500 mL;

Sealing and leakproof: high temperature sealing (adjustable from 100 to 200 ° C) + pressure adaptive adjustment to ensure the sealing of sauce packaging;

Intelligent deviation correction: the photoelectric tracking system automatically corrects the packaging film pattern to improve the appearance of the finished product.

Product Advantages

High hygiene standards

The sauce contact part is made of food-grade stainless steel (304/316L), which meets the requirements of HACCP and GMP certification.

Reduce costs and increase efficiency

The automatic waste film recovery system reduces material waste and reduces production energy consumption by 15%;

One-button cleaning function shortens downtime and improves equipment utilization.

Strong compatibility

Adapts to a variety of packaging materials (PP cups, aluminum foil films, composite films, etc.), and supports customized filling heads to deal with special sauces (such as sauces containing particles).

Applicable scenarios

Food processing plants: production of pre-prepared food sauce packages, compound condiments, and ready-to-eat sauces;

Catering supply chain: central kitchen sauce packaging, chain fast food customized packaging;

Emerging categories: healthy light meal sauces, pet food seasoning sauces, etc.

This equipment is specially developed for the sauce industry. With high-precision filling, strong sealing and corrosion-resistant design as its core advantages, it can solve the problems of dripping, loose sealing and equipment cleaning in the sauce filling process, help enterprises achieve standardized and large-scale production, and improve product quality and market competitiveness.