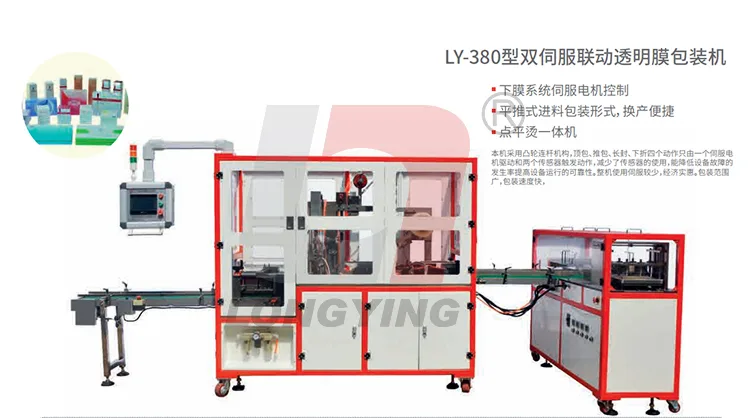

In the context of continuous iteration and upgrading of packaging equipment, enterprises have increasingly stringent requirements for packaging efficiency, precision, and adaptability. As a deep cultivator in the packaging machinery field, Longying has launched the LY-380 transparent film 3D packaging machine based on the LY-300 series. With stronger performance, wider applicability, and more intelligent operation, it has become an ideal choice for medium and large production enterprises. This equipment not only inherits the quality genes of the Longying brand but also achieves breakthroughs in speed, stability, and versatility, providing efficient packaging solutions for the food, pharmaceutical, cosmetics, and other industries.

I. Core Performance Upgrades of Longying LY-380

(1) Ultra-High-Speed Packaging, Efficiency Reaches New Heights

The most significant upgrade of Longying LY-380 lies in its breakthrough packaging speed. Through the optimized mechanical transmission system and servo control technology, its maximum packaging speed reaches 400 packs per minute, which is more than 30% higher than that of LY-300. This performance is of great significance for large-scale production enterprises – taking the biscuit production line in the food industry as an example, the daily output can increase by nearly 100,000 packs, easily coping with the peak season order pressure.

The equipment adopts dual servo motors to drive the film feeding and conveying mechanisms, combined with a high-precision cam divider to ensure stability during high-speed operation. Even in the state of continuous 8-hour full-load operation, the packaging error can still be controlled within ±0.5mm, avoiding problems such as packaging skew and film tearing caused by increased speed. At the same time, the feeding system of the equipment adopts an adjustable guide rail design, which can be compatible with various products with lengths of 50-300mm, widths of 30-200mm, and heights of 10-150mm, achieving the flexible performance of “high-speed without picking products”.

(2) Intelligent Control System, More User-Friendly Operation

LY-380 is equipped with a new generation of PLC control system and a 10.1-inch color touch screen, making the operation interface more intuitive and easy to understand. The system has a built-in memory function for 100 sets of product parameters, supporting one-click recipe calling, and the product change time is shortened to less than 3 minutes – for cosmetics enterprises that need to frequently switch product specifications, this function can reduce nearly 50% of downtime losses.

The equipment adds an AI visual inspection module, which can real-time identify the positioning marks of the packaging film and the edge of the product through a high-definition camera, automatically calibrate the film feeding speed and cutting position, and increase the film utilization rate by 8%-12%. When detecting material shortage, exhausted film, or abnormal packaging, the system will immediately stop and issue an acousto-optic alarm, and display the fault point diagram on the screen to reduce the difficulty of manual troubleshooting. In addition, the equipment supports docking with the factory MES system, which can upload production data in real-time, facilitating enterprises to monitor production capacity and trace quality.

(3) Reinforced Structural Design, Comprehensive Improvement in Durability

To adapt to high-speed and high-frequency operation requirements, the key components of LY-380 have been comprehensively strengthened: the machine body is welded with 8mm thick steel plates, increasing the load-bearing capacity by 40%; the film feeding roller is treated with chrome plating process, with a surface hardness of HRC55 or more, and the wear resistance is extended to 15,000 hours; the heat-sealing knife is made of imported high-temperature resistant alloy material, which can withstand continuous 12-hour high-temperature operation at 200℃ without deformation.

The folding mechanism of the equipment adopts an eccentric shaft adjustment design, which can accurately control the folding angle by rotating the knob, adapting to film materials of different thicknesses (from 20μm to 80μm can run stably). This design not only reduces maintenance costs but also ensures a flat and wrinkle-free packaging effect when handling thicker scratch-resistant films or composite films.

II. In-Depth Adaptation to Multi-Industry Scenarios

(1) Pharmaceutical Industry: Dual Guarantee of Compliance and Efficiency

In the field of pharmaceutical packaging, LY-380 is strictly designed in accordance with GMP standards. The parts in contact with drugs are made of 316L stainless steel, which can withstand high-temperature steam sterilization. The packaging process of the equipment is completely free of manual contact, effectively reducing the risk of cross-contamination. For tablets and capsules packaged in aluminum-plastic plates, the heat-sealing temperature can be precisely controlled at 120-180℃ to ensure tight sealing of the aluminum-plastic edges, meeting the storage requirements of drugs for moisture-proof and anti-oxidation.

After a large pharmaceutical enterprise introduced LY-380, the daily output of its Ganmaoling Granule packaging line increased from 150,000 boxes to 220,000 boxes. Moreover, due to the improved packaging tightness, the product’s shelf life was extended by 6 months, and the customer complaint rate decreased by 70%.

(2) Food Industry: High-Speed Response to Mass Production

For mass-produced foods such as biscuits, chocolates, and egg tarts, the high-speed performance of LY-380 can give full play to its advantages. The equipment supports pre-stretching treatment of the transparent film, making the film closely fit the food packaging box, which not only saves materials but also highlights the product appearance. For oily and sugary foods, its anti-stick heat-sealing knife can avoid packaging damage caused by film adhesion, and the rejection rate is controlled below 0.3%.

In the baking industry, a chain brand uses LY-380 to package 手撕面包 (shredded bread). Through the equipment’s “anti-pressure injury” mode, the clamping force is automatically adjusted during high-speed conveying to avoid bread deformation, increasing the product qualification rate from 95% to 99.5%.

(3) Cosmetics and Luxury Goods: Exquisite Packaging Highlights Quality

The cosmetics and luxury goods industry has extremely high requirements for the aesthetics of packaging. The high-precision folding mechanism of LY-380 can realize precise 45-degree edge folding of the film, with flat edges and no burrs. The equipment supports processes such as gold stamping and embossing on the transparent film, and with the optional holographic film positioning system, it can form three-dimensional anti-counterfeiting patterns on the packaging surface, enhancing the high-end sense of the product.

A high-end perfume brand uses LY-380 to package gift boxes. Through the equipment’s synchronous gold stamping function, the brand LOGO is stamped at the designated position of the film. The pattern clarity is 30% higher than that of traditional equipment, the product’s recognition in counters is significantly enhanced, and the repurchase rate is increased by 15%.

(4) Electronics and Stationery Industry: Both Protection and Display

For small precision products such as mobile phone accessories, pens, and USB drives, the gentle clamping system of LY-380 can avoid scratch damage during packaging. The equipment supports the use of anti-static film materials to meet the packaging needs of electronic components. In the stationery industry, its high-speed packaging capacity can cope with the mass production of notebooks and stationery boxes. The transparent film packaging can not only display product patterns but also prevent wear during transportation.

III. Core Value Created for Enterprises

(1) Reduce Costs and Increase Efficiency, Raise the Ceiling of Production Capacity

The high-speed performance of LY-380 directly drives the increase in production capacity. Calculated by running 16 hours a day, the annual production capacity can reach 15-20 million pieces, an increase of more than 5 million pieces compared with traditional equipment. The improvement of film utilization rate and the reduction of rejection rate reduce the packaging cost per product by 0.05-0.1 yuan. For enterprises with an annual sales volume of 10 million pieces, the annual cost can be saved by 500,000-1,000,000 yuan.

According to the calculation of a daily necessities enterprise, after introducing LY-380, the number of personnel on the packaging line of its laundry detergent packaging boxes was reduced from 5 to 2, the annual labor cost was reduced by 360,000 yuan, and the investment payback period was only 8 months.

(2) Flexible Production, Quick Response to Market Changes

In the current era of increasingly personalized consumer demand, small-batch and multi-category production has become a trend. The rapid product change capability and wide adaptation range of LY-380 enable enterprises to switch products of different specifications on one production line. For example, a food enterprise can package 200ml sauce bottles in the morning and switch to 500g biscuit boxes in the afternoon without changing the mold, which can be completed only by parameter adjustment.

This flexible production capacity helps enterprises shorten the product launch cycle and seize the opportunity in new product testing and promotional activities. With the flexibility of LY-380, a snack brand successfully launched 10 customized packaging gift boxes before the Spring Festival, with sales increasing by 40% year-on-year.

(3) Compliant Production, Avoid Quality Risks

In strictly regulated industries such as pharmaceuticals and food, compliance is the bottom line of production. The design of LY-380 meets international standards such as FDA and CE. The temperature, speed, and other parameters during the operation of the equipment can be recorded and exported in real-time, facilitating inspection by regulatory authorities. Its stable packaging quality reduces the risk of product recall caused by poor sealing, avoiding potential economic losses and brand reputation damage for enterprises.

IV. Analysis of Technological Innovation Points

(1) Adaptive Film Material Processing System

LY-380 is equipped with an intelligent film tension control system, which can automatically adjust the tension according to the thickness and material of the film. From the thin BOPP film to the thick composite film, it can maintain stable conveying. The system has a built-in film database, presetting the processing parameters of 20 common film materials. Operators only need to select the film type, and the equipment can automatically match the best parameters, reducing the operation difficulty.

(2) Modular Expansion Design

The equipment adopts a modular architecture. In addition to the basic packaging function, it can be equipped with coding machines, labeling machines, weighing and testing devices, and other modules as needed. For example, pharmaceutical enterprises can add a drug regulatory code encoding module to realize synchronous printing of packaging and traceability codes; food enterprises can add a metal detection module to ensure product safety. This design enables the equipment to have continuous upgrading capability, extending the service life to more than 10 years.

(3) Energy-Saving and Consumption-Reducing Technology

The heating system of LY-380 adopts infrared heating technology, with thermal efficiency 40% higher than that of traditional resistance heating, and power consumption per hour reduced by 1.5 kWh. The servo motor of the equipment adopts vector control technology, and the energy consumption is reduced by 30% during low-speed operation. Calculated by running 16 hours a day, the annual electricity bill can be saved by about 8,000 yuan.

V. Conclusion

Longying LY-380 transparent film 3D packaging machine provides medium and large production enterprises with a packaging solution that balances efficiency and quality through speed upgrading, intelligent optimization, and structural strengthening. Its in-depth adaptation capability in multiple industries makes it not only a piece of equipment but also an important part of the enterprise’s flexible production system.

In today’s increasingly fierce market competition, efficient, stable, and flexible packaging capabilities have become the key for enterprises to reduce costs, increase efficiency, and seize the market. Longying LY-380, with technological innovation as the core, continues to create value for enterprises. Whether it is a food enterprise with large-scale production or a luxury brand pursuing exquisite packaging, it can find a suitable packaging solution. Choose LY-380 to make the packaging link a booster for enterprise development rather than a bottleneck.