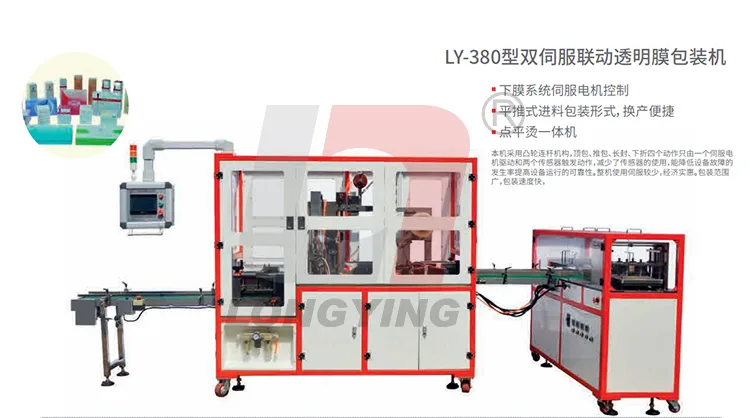

In the era of the “appearance economy”, the packaging of cosmetic products has become an important factor in attracting consumers. An exquisite and high-end packaging can not only increase the added value of products but also highlight the brand’s tone and strength. Longying LY-380 transparent film 3D packaging machine is specially designed for the cosmetics industry. With its excellent packaging effect, efficient production capacity and flexible adaptability, it has become the ideal choice for cosmetics enterprises to improve the quality of product packaging, putting a “delicate coat” on cosmetic products.

Enhance Packaging Grade and Highlight the Charm of Cosmetic Brands

As a carrier of fashion and beauty, cosmetic products require packaging with high-end and exquisite visual effects to impress quality-pursuing consumers. Longying LY-380 transparent film 3D packaging machine adopts transparent film 3D packaging technology, which can create a highly textured packaging effect for cosmetic products, instantly enhancing the grade of the products.

The transparent film has good transparency and gloss. After being packaged by LY-380, it can clearly display the appearance design, brand logo and color matching of cosmetic products, allowing consumers to intuitively feel the charm of the products without opening the package. At the same time, the tight and flat packaging effect formed by the 3D packaging of the transparent film endows the product with a high-end and exquisite texture, which is in line with the fashion positioning of cosmetic products.

For example, for single cosmetic products such as lipsticks, eyeshadow palettes and foundations, after 3D packaging with transparent film by LY-380, it can not only protect the original packaging of the products from damage but also make the products more eye-catching on the shelf, attracting consumers’ attention. For cosmetic gift sets, LY-380 can perfectly package multiple items together to form an integrated, beautiful and elegant gift box, further enhancing the gifting and collection value of the gift box, and helping the brand establish a unique image in the fierce market competition.

Efficient and Stable Production to Meet the Mass Needs of Cosmetics Enterprises

The market demand for the cosmetics industry is often seasonal and fashionable. During important festivals or new product launches, enterprises need to quickly complete mass production and packaging tasks. Longying LY-380 transparent film 3D packaging machine, with its efficient and stable production performance, can easily meet the mass production needs of cosmetics enterprises.

The equipment adopts advanced mechanical structure and intelligent control system, realizing fully automatic operation from product conveying, transparent film wrapping to heat sealing forming, which greatly improves the packaging efficiency. Compared with traditional manual packaging or semi-automatic packaging equipment, LY-380 has a faster packaging speed, which can complete a large number of packaging tasks per hour, effectively shortening the production cycle and ensuring that products are launched on the market in time.

At the same time, LY-380 still maintains good stability during high-speed operation. The equipment is equipped with a high-precision positioning system and sensors, which can accurately control the tension of the transparent film, wrapping position and heat sealing temperature, ensuring that the packaging of each cosmetic product is neat and uniform, without wrinkles or bubbles. Stable packaging quality not only reduces the production of unqualified products, lowers production costs but also ensures the consistency of products during transportation and storage, enhancing the brand’s reputation.

Comprehensive Protection of Products to Ensure the Quality and Safety of Cosmetics

Cosmetic products often contain a variety of chemical components and have high requirements for storage environment, needing to avoid moisture, pollution and high-temperature exposure. Longying LY-380 transparent film 3D packaging machine can provide comprehensive protection for cosmetic products, ensuring their quality and safety.

The transparent film has good moisture-proof and dust-proof performance. After being tightly wrapped and heat-sealed by LY-380, it can form a sealed packaging environment, effectively isolating external moisture, dust and bacteria, preventing cosmetic products from deteriorating due to moisture and affecting use safety due to pollution. For some fragile cosmetic products, such as glass bottled nail polish and pressed powder, 3D packaging with transparent film can also play a certain buffering role, reducing damage to products caused by collision and extrusion during transportation.

In addition, the transparent film material used by LY-380 meets food-grade and cosmetic-grade safety standards, will not release harmful substances, ensuring no pollution to cosmetic products, so that consumers can use them with confidence. This comprehensive protection function provides a strong guarantee for the quality and safety of cosmetic products, allowing the brand to win consumers’ trust.

Flexible Adaptation to Meet the Personalized Needs of Cosmetic Products

There are a wide variety of cosmetic products with different shapes and packaging specifications, such as the slender shape of lipsticks, the square shape of eyeshadow palettes, and the cylindrical shape of foundations, which put high requirements on the adaptability of packaging equipment. Longying LY-380 transparent film 3D packaging machine has excellent flexibility and adaptability, which can meet the personalized packaging needs of different cosmetic products.

The parameters of the equipment can be flexibly adjusted according to the size, shape and packaging requirements of cosmetic products. Operators only need to simply set parameters such as the length of the transparent film, wrapping force and heat sealing time through the equipment’s control system to quickly adapt to the packaging needs of different products. Whether it is small lipsticks, eyebrow pencils or large cosmetic gift boxes, LY-380 can complete the packaging task accurately.

For some cosmetic products with special shapes, such as eyeshadow palettes with three-dimensional patterns and perfumes with irregular bottle shapes, LY-380 can also perfectly fit the contour of the product through precise positioning and wrapping, showing the unique design of the product. This flexible adaptability enables cosmetics enterprises to avoid equipping separate packaging equipment for different products, reducing equipment investment costs, and at the same time improving production flexibility and efficiency, helping enterprises quickly respond to market changes and launch more diversified cosmetic products.

Intelligent Operation and Management to Reduce Production Difficulty and Cost

Longying LY-380 transparent film 3D packaging machine is equipped with an advanced intelligent control system, making operation more convenient and management more efficient, which helps reduce the production difficulty and cost of cosmetics enterprises.

The equipment adopts a humanized human-computer interaction interface, presenting various operation functions and parameter settings in the form of a touch screen. The interface is concise and intuitive, easy to understand and operate. Operators can master the use of the equipment proficiently after simple training, quickly completing the setting of production parameters, production start-up and status monitoring, reducing the requirements for operators’ skill levels and cutting training costs.

At the same time, the equipment is equipped with intelligent monitoring and fault diagnosis functions, which can monitor the operation status of the equipment in real-time, such as packaging speed, remaining transparent film, working temperature of various parts of the equipment, etc. When there is an abnormality in the equipment, the system will automatically send an alarm signal and display the cause of the fault and troubleshooting suggestions on the interface, helping operators quickly check and solve problems, reducing equipment downtime and improving production efficiency.

The intelligent control system can also record and count production data in real-time, such as packaging quantity, production time and equipment utilization rate, providing accurate data support for enterprise production management. Managers can understand production progress, equipment operation status and other information through these data, reasonably arrange production plans, optimize production processes, further reduce production costs and improve the enterprise’s management level.

Choose Longying LY-380 to Empower Cosmetic Brands

Longying LY-380 transparent film 3D packaging machine provides a one-stop high-end packaging solution for the cosmetics industry with its advantages of enhancing packaging grade, efficient and stable production, comprehensive product protection, flexible adaptation to diversity and intelligent operation and management.

It can not only help cosmetics enterprises create attractive product packaging, enhance brand image and market competitiveness but also improve production efficiency and reduce production costs, injecting strong impetus into the development of enterprises. Whether it is a start-up cosmetic brand or a mature large cosmetics enterprise, they can realize the upgrading of product packaging and the improvement of production efficiency by using Longying LY-380 transparent film 3D packaging machine.

If your cosmetics enterprise is looking for a packaging equipment that can improve product packaging quality and meet diversified production needs, you may wish to choose Longying LY-380 transparent film 3D packaging machine. Contact us immediately to learn more about the equipment details, let it add luster to your cosmetic products and help your brand shine more charm in the cosmetics market.