LONGYING specializes in innovative packaging technologies for traditional foods, delivering automated and high-precision packaging solutions tailored for industrial-scale production of mooncakes, zengao, zongzi, and other traditional delicacies.

Intelligent Sealing Technology: Features precise temperature control and pressure adjustment to ensure smooth, aesthetically pleasing seals while preserving artisanal texture.

Flexible Production Design: Enables quick mold and parameter changes with one-touch operation, accommodating multiple product specifications to enhance efficiency.

Food-Grade Safety Standards: Constructed with 304 stainless steel and GMP-certified components to guarantee food safety compliance.

With high stability and low waste rates as core advantages, LONGYING production lines empower businesses to scale traditional craftsmanship without compromising quality—blending authentic flavor with modern efficiency.

Preserving Tradition, Engineering the Future — LONGYING Equipment.

Longying’s production line employs specialized sealing equipment tailored to the characteristics of different traditional foods, ensuring quality and safety:

Designed specifically for tray/plastic box packaging with precise positioning.

Utilizes heat sealing or hot-cut cold sealing technology to achieve high-strength sealing between the lid film and the base box.

Key Points: Smooth, aesthetically pleasing finish; oxygen and moisture barrier; locks in filling flavor; extends shelf life.

Core technology lies in the vacuum sealing process.

Removes air from the packaging bag and immediately performs heat melt sealing.

Key Points: Inhibits bacterial growth; maintains the zongzi’s firm and springy texture; significantly extends the shelf life of fresh zongzi.

Often an integrated filling and sealing machine.

Precisely fills viscous jingao into bowls/cups, followed by high-speed automatic film covering and heat sealing.

Key Points: Leak-proof, hermetic seal; flat seal facilitates subsequent steam sterilization; ensures soft, glutinous texture.

Typically employs pillow packaging or vertical bag packaging.

Uses continuous heat-press sealing to rapidly complete back sealing and end sealing.

Key Points: High-efficiency continuous operation; strong seal prevents breakage; light-blocking and moisture-proof protection for the flaky pastry and filling.

A:Models with different capacities such as one-out-of-six, one-out-of-eight, and one-out-of-ten can achieve an hourly output of approximately 6,000 boxes, which can at least increase your production efficiency by 10 times and greatly reduce labor costs.

A:In addition to mooncakes, they are also suitable for the packaging of boxed traditional foods such as egg yolk puffs, mung bean cakes, wife cakes, durian puffs, etc. We are professional in manufacturing sealing machines.

A :Our Longying fully automatic mooncake sealing machine features automatic cup loading, automatic spacer placement, and automatic film sealing. It also supports optional automatic oxygen absorber dispensing, and can be equipped with coding or marking functions as needed.

A:

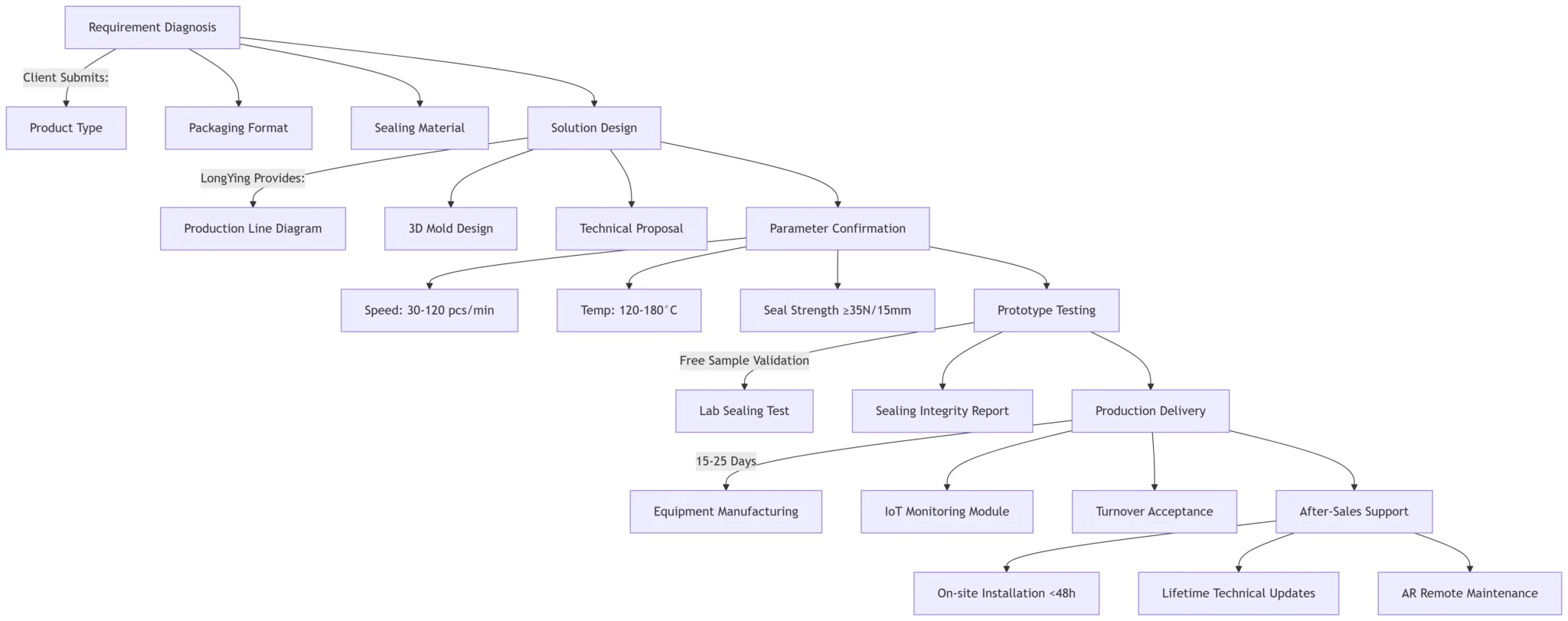

A :Generally, there is no stock available, as products are customized according to customer requirements. The delivery cycle is approximately 20 days.

Yes, we offer lifelong warranty, on-site installation, and training.

A :

A :

We are willing to serve the society with our wisdom and ability and become your trusted partner.