Overview

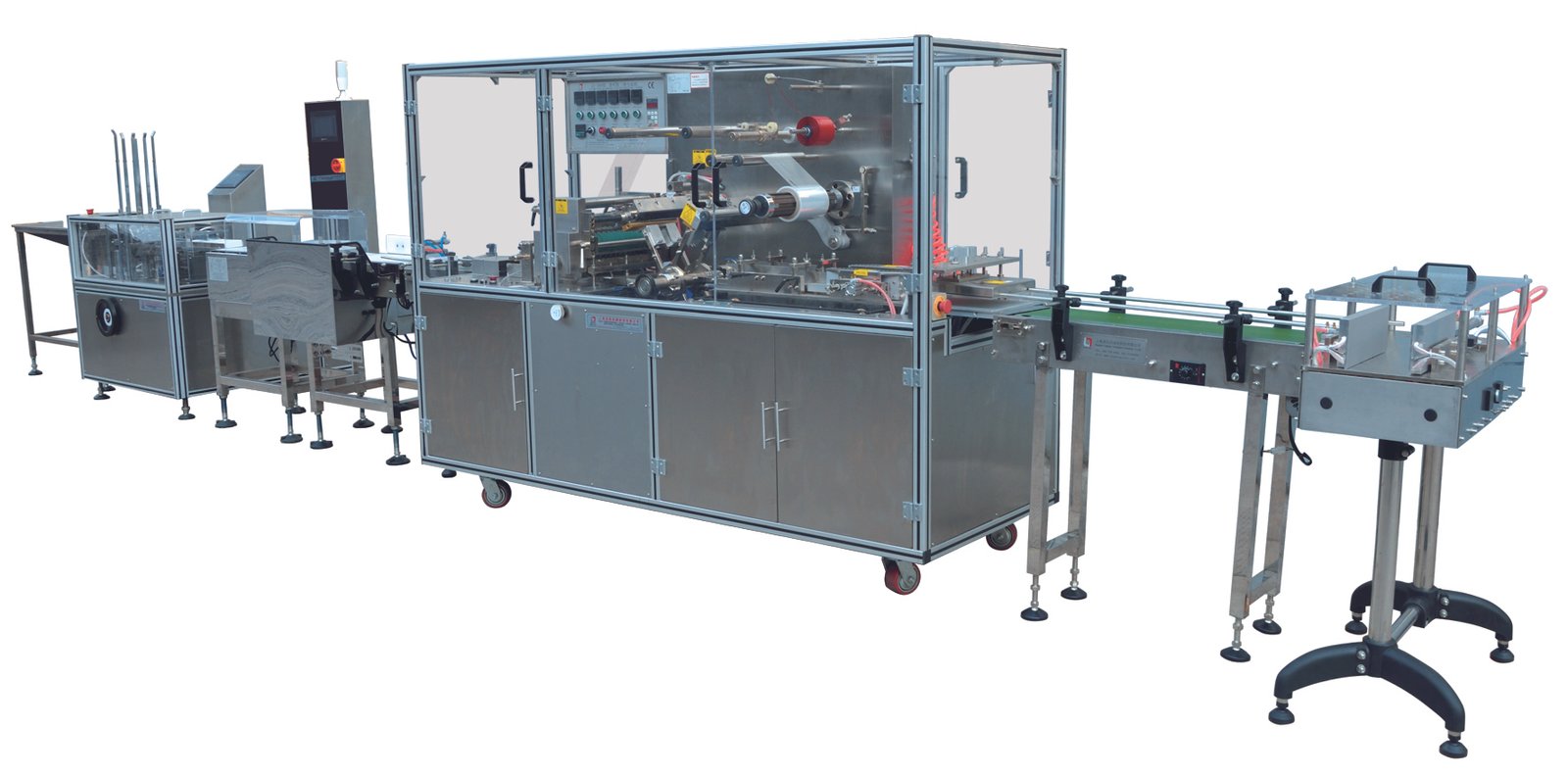

The LY-300 Adjustable Transparent Film 3D Packaging Machine is designed to wrap rigid paper boxes and packaged goods of various sizes using cellophane or BOPP double-sided heat-sealable film. Developed by integrating advanced domestic and international technologies, this machine combines mechanical linkage systems, stepless variable frequency speed control, and automated electrical components into a compact, lightweight, and highly automated unit. Its user-friendly touchscreen interface, ergonomic design, and easy maintenance make it ideal for small to medium-sized boxed items across industries such as pharmaceuticals, health supplements, cosmetics, food, stationery, DVDs, playing cards, and cigarettes. The machine enhances product value with anti-counterfeit and moisture-proof packaging while elevating aesthetics and brand appeal.

Key Features & Technical Highlights

Advanced Control System

PLC-based automation with optional servo-driven film feeding (note: servo mode cannot synchronize with tear strip application).

Touchscreen interface for intuitive operation and real-time monitoring.

Safety & Compliance

CE-certified safety design: Automatically stops when doors are opened, ensuring operator safety.

Flexible Speed & Adaptability

Infinitely adjustable packaging speed via frequency converter to match production demands.

Quick size adjustment: Easily adapt to different product dimensions by replacing molds and minor calibration.

Precision Thermal Management

Microcomputer-controlled heating plates automatically adjust temperatures based on ambient conditions, maintaining consistent sealing quality.

Seamless Packaging Process

Integrated workflow: Film dispensing, cutting, folding, heat sealing, shaping, and ejection ensure smooth, wrinkle-free wrapping.

Hot-sealed side folds provide airtight, moisture-resistant, and visually refined finishes.

Packaging Process & Anti-Counterfeit Functionality

The LY-300 feeds items into a storage hopper, then executes a fully automated sequence:

Film Dispensing & Cutting: Precisely measures and cuts film to size.

Folding & Sealing: Mechanically folds film around the item, with heat-sealed edges for durability.

Anti-Counterfeit Integration: Applies a pre-printed or holographic tear strip (e.g., gold/silver “pull-open” line) via pressure-sensitive adhesive, enabling easy opening while deterring tampering.

Compatible Packaging Materials

Transparent Cellophane: Heat-sealable, moisture-resistant, and glossy.

BOPP Double-Sided Heat-Sealable Film: Thickness 22μ–28μ for durability and clarity.

Tear Strips:

Width: 1.2–3mm (pressure-sensitive adhesive, multiple color options).

Designs: Transparent, metallic (gold/silver), printed text (red/gold on white), laser anti-counterfeit patterns, laser-cut (openwork) designs.

Applications

Pharmaceuticals & Nutraceuticals: Secure, tamper-evident packaging for medicine boxes and supplements.

Food & Cosmetics: Hygienic, visually appealing wraps for snacks, skincare, and luxury goods.

Media & Lifestyle: Protective and stylish packaging for DVDs, playing cards, cigarettes, and stationery.

Why Choose the LY-300?

Combining cutting-edge automation with rugged reliability, the LY-300 delivers high-speed, precision packaging while reducing downtime and material waste. Its anti-counterfeit features, compact footprint, and touchscreen simplicity make it a cost-effective solution for enhancing product integrity and market competitiveness.