Overview

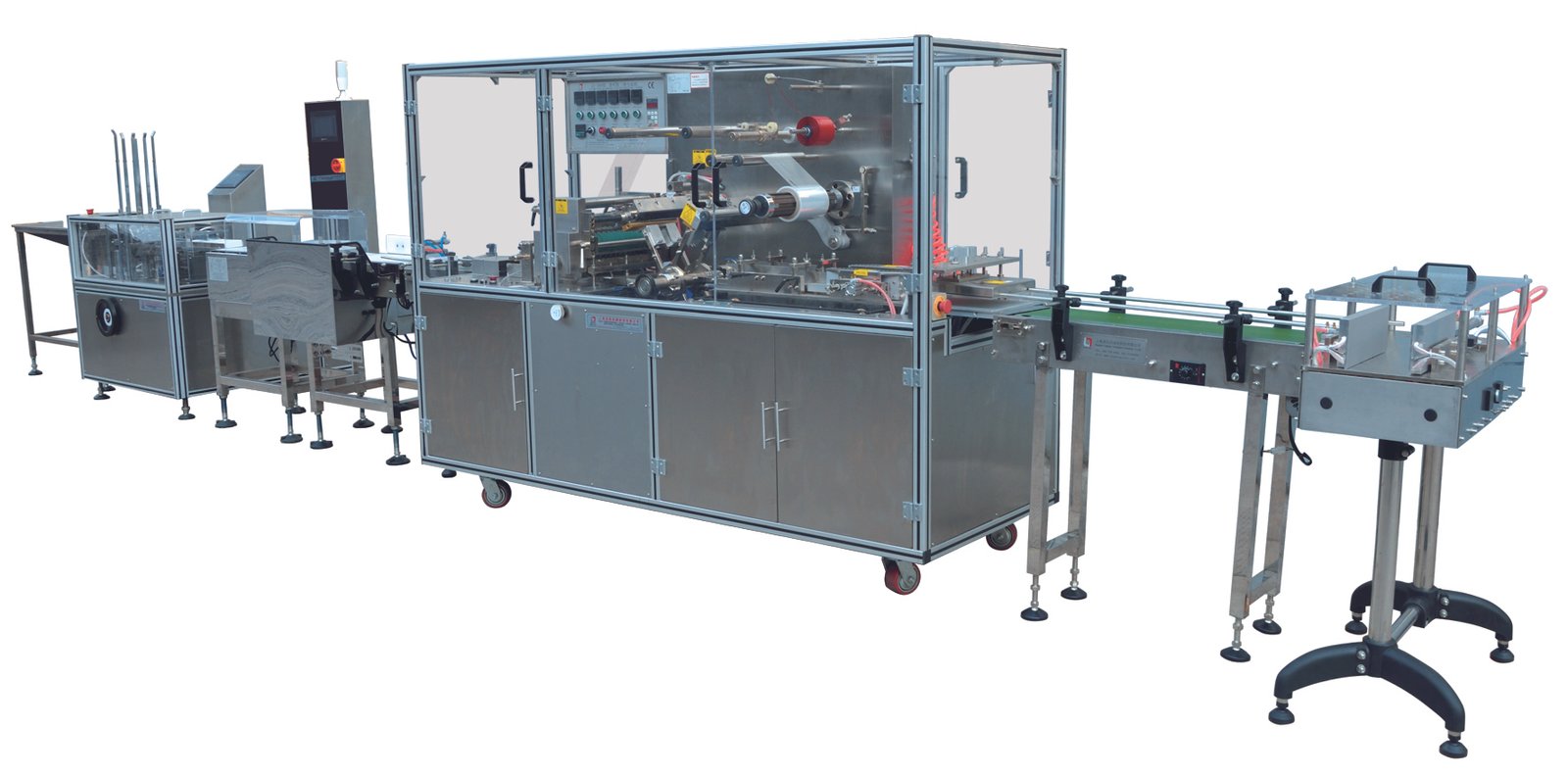

The LY-350 is a state-of-the-art, fully automated packaging solution that seamlessly integrates mechanical, electrical, and pneumatic systems for high-speed, precision wrapping of boxed items. Designed for both horizontal and vertical packaging orientations (customizable to user needs), it delivers airtight, moisture-proof, and visually polished finishes while incorporating a tamper-evident tear line for secure yet easy package access. Ideal for industries demanding efficiency, reliability, and premium presentation, the LY-350 excels in applications ranging from pharmaceuticals to luxury goods.

Key Features

6-Axis Servo-Driven Precision

Equipped with 6 servo-controlled axes (film feeding, top/bottom pushing, longitudinal sealing, folding, and side sealing) to ensure smooth operation, minimal mechanical wear, and exceptional reliability.

Adaptable Horizontal Push-Type Packaging

Horizontal push mechanism enables rapid mold changes and compatibility with diverse right-angled box sizes.

Combines stability, secure sealing, and aesthetic appeal with low maintenance requirements.

Dual Sealing Modes

Spot Sealing: Localized adhesion for flexible material handling.

Flat Sealing: Full-surface bonding for maximum durability and sleek finishes.

Intelligent Film Control

Servo-driven film feeding system allows precise length adjustment, reducing waste and enhancing adaptability to varying product dimensions.

Safety & User-Friendly Operation

Emergency stop buttons on the control panel and feeding conveyor.

Automatic shutdown during jamming or safety breaches (e.g., box pusher safety sensors).

Intuitive HMI Interface: Features manual/auto modes, real-time counters, adjustable film length, and speed settings for effortless control.

Linear Conveyor Integration

Straight-line feeding design simplifies integration into existing production lines, optimizing workflow efficiency.

Technical Advantages

High Cost-Performance Ratio: Combines advanced automation with affordability.

Broad Packaging Range: Handles boxes of various sizes and industries.

Rapid Speed & Stability: Maximizes output without compromising quality.

Tamper-Evident Design: Integrated tear line enhances security while maintaining consumer convenience.

Applications

Pharmaceuticals: Secure, hygienic wrapping for medicine boxes.

Luxury Goods: Premium finishes for cosmetics, watches, or electronics.

Food & Beverage: Moisture-proof packaging for snack boxes or tea cartons.

Consumer Products: Durable wraps for books, stationery, or small appliances.

Why Choose the LY-350?

The LY-350 redefines efficiency with its servo-driven precision, dual sealing flexibility, and robust safety features. Its modular design and user-centric interface empower businesses to scale production while maintaining consistent, high-quality packaging standards. Whether upgrading existing lines or launching new products, the LY-350 offers a competitive edge through speed, versatility, and reliability.