Equipment Features

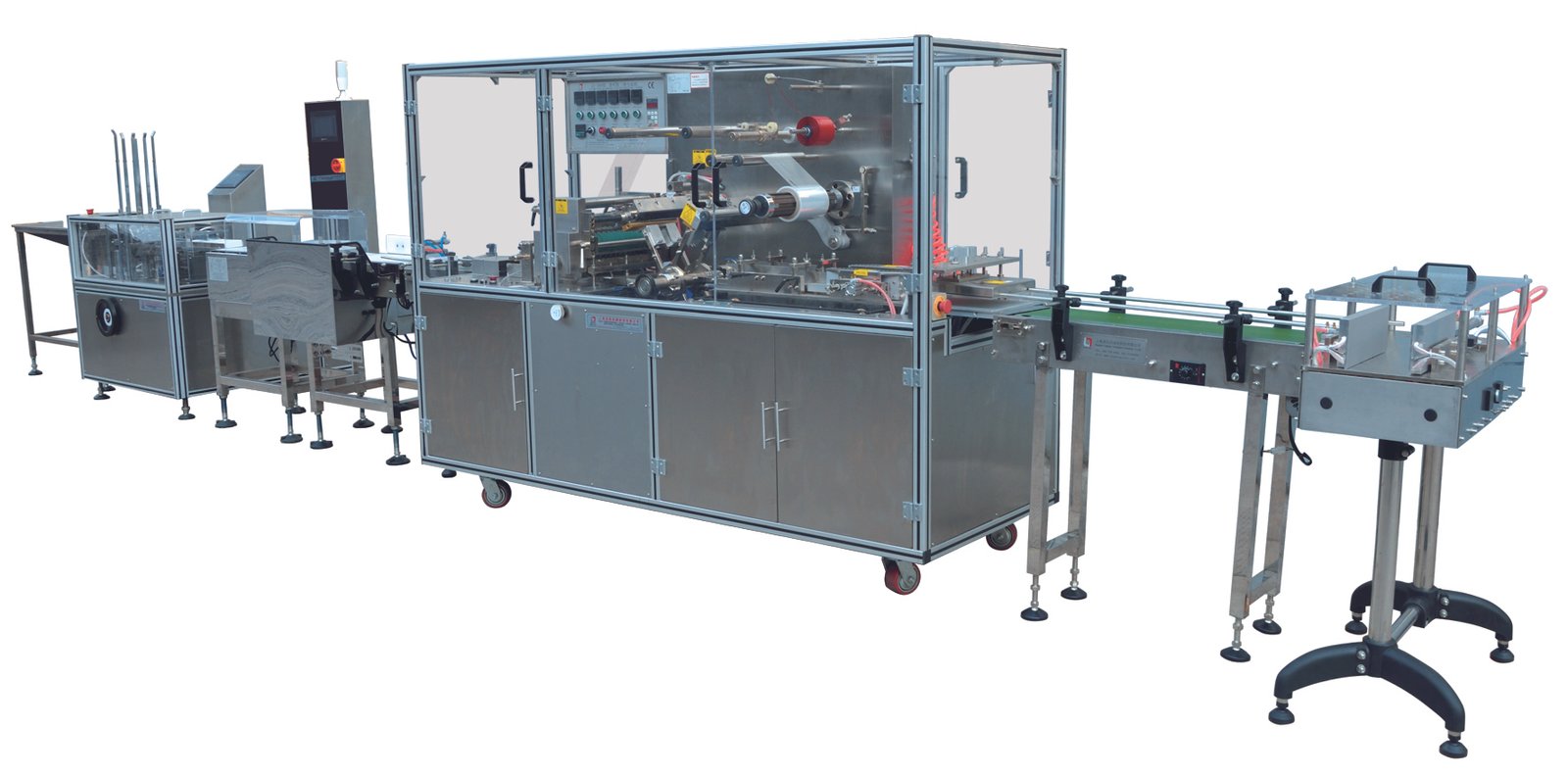

The LY-380 fully automatic transparent film packaging machine is an integrated mechanical, electrical, and pneumatic system. It utilizes a conveyor belt to supply items for packaging, with mechanisms for film unwinding, folding, and sealing to encapsulate products. The folding section employs heat sealing to ensure tight, aesthetic, and moisture-resistant packaging. The film is bonded with a tear line for easy opening of the finished product.

This machine adopts a cam linkage mechanism, where four actions—lifting, pushing, long sealing, and bottom folding—are driven by a single servo motor and triggered by one sensor. This design reduces sensor usage, minimizes failure rates, and enhances operational reliability. With fewer servos, the machine is cost-effective while offering broad packaging compatibility and high-speed performance, giving it a clear market advantage.

Functional Highlights

Servo-Controlled Film Feeding: The lower film system is driven by a servo motor, allowing flexible adjustment of film length for superior adaptability.

Horizontal Push-Type Packaging: Designed for horizontal packaging and box feeding, this machine enables quick mold changes with strong mold versatility, suitable for various rectangular box-shaped products. It ensures stable operation, secure sealing, smooth aesthetics, and easy maintenance.

Dual Sealing Modes: Supports both spot sealing and flat sealing functions.

Hygienic Design: Constructed with a frame and transparent acrylic protective cover, meeting hygiene standards and offering an elegant appearance.

Safety and Automation:

Emergency stop buttons on the operation side and feed conveyor.

Automatic shutdown triggered by box jams via a safety mechanism on the pusher.

User-friendly interface with manual mode (for individual adjustments) and auto mode (with speed, film length, and counting settings).

Linear Conveyor Feed: Facilitates seamless integration into production lines.

Applications

Primarily used for outer packaging of boxed items, supporting both horizontal and vertical packaging configurations (customizable to user needs). Ideal for enhancing product presentation, moisture resistance, and ease of unboxing.