Key Features

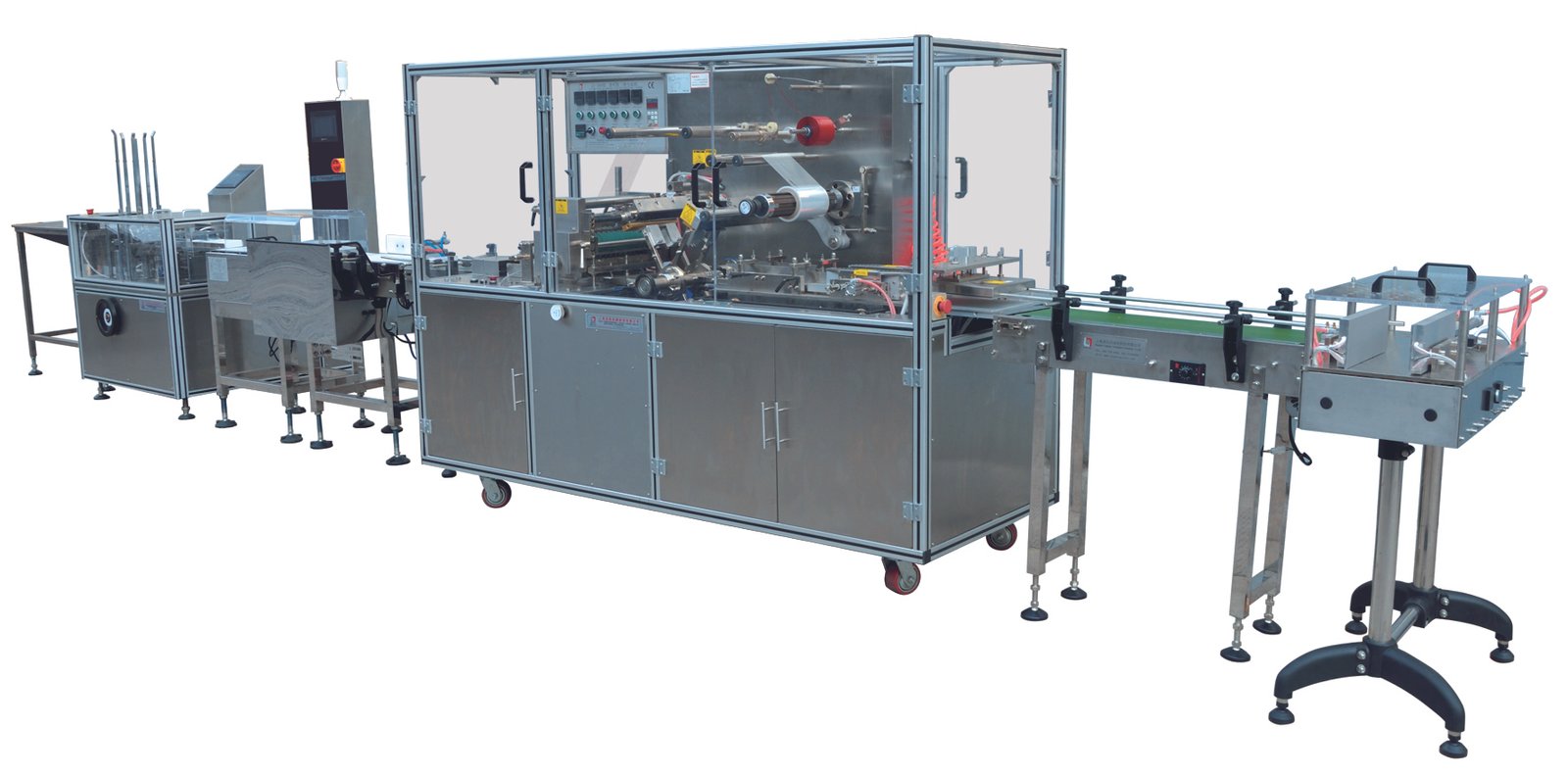

Advanced Design: Meticulously redesigned based on cutting-edge international technologies, ensuring superior performance and reliability.

Automated Process: Executes automatic film feeding, cutting, box pushing, side folding, and heat sealing for seamless, efficient operation.

Secure & Aesthetic Seals: Delivers tamper-evident, moisture-proof, and dust-resistant packaging with visually polished, wrinkle-free finishes.

Compact & User-Friendly: Space-saving structure, intuitive controls, and tool-free mold changes simplify operation and maintenance.

Versatile Adaptability: Accommodates various box sizes with minimal mold adjustments, ideal for small-batch production.

Durability: Robust construction ensures long-term stability even in demanding environments.

Applications

The LY-380 specializes in 3D transparent film wrapping for square or rectangular single-unit items across industries such as:

Pharmaceuticals: Hygienic, tamper-proof packaging for medicine boxes and blister packs.

Cosmetics & Personal Care: Elegant presentation for lipstick tubes, skincare jars, and gift sets.

Health Supplements & Food: Protective wraps for vitamin bottles, tea boxes, or premium snacks.

Small Electronics: Secure packaging for accessories, cables, or compact devices.

Technical Advantages

Anti-Counterfeit Protection: Integrated sealing deters tampering, enhancing brand trust.

Quick Changeover: Swap molds in minutes to switch between product dimensions.

Cost-Effective: Optimized for small to medium-scale production with low material waste.

Why Choose the LY-380?

Perfect for businesses seeking a semi-automatic, heavy-duty solution, the LY-380 balances affordability with professional-grade results. Its simplicity, adaptability, and compact footprint make it ideal for startups, labs, or niche manufacturers aiming to elevate packaging quality without heavy automation investments.