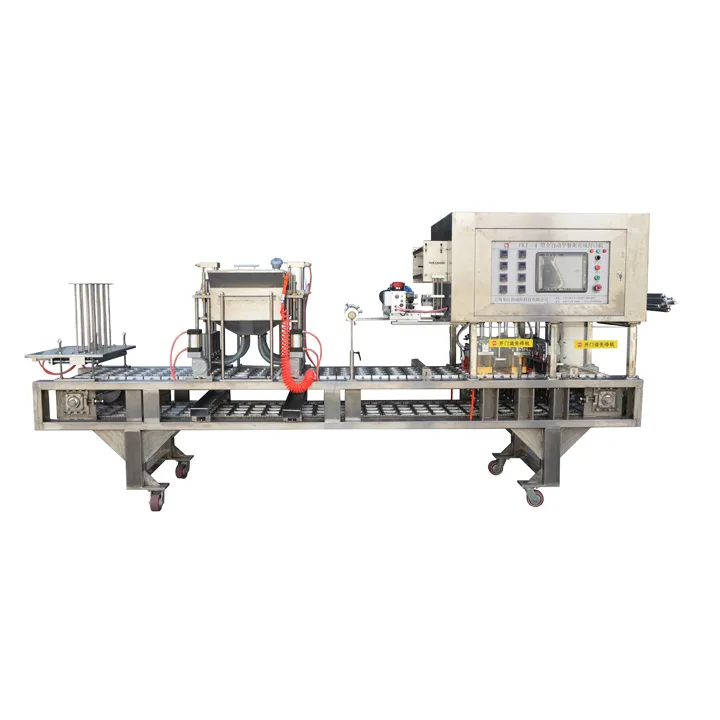

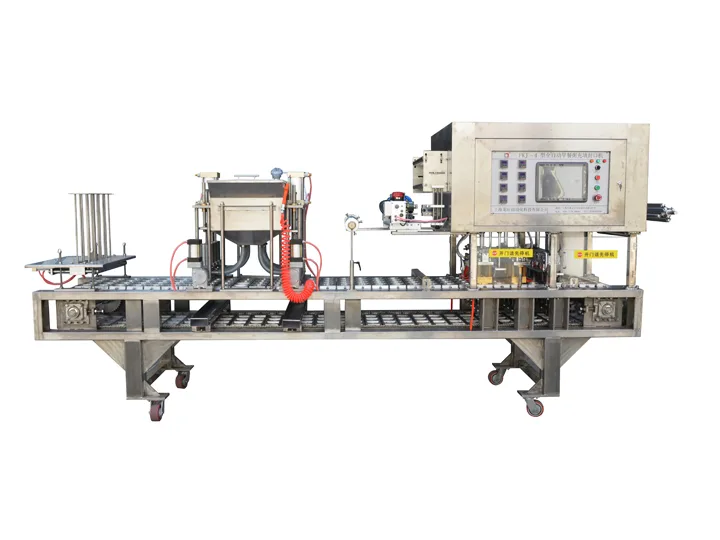

Equipment Features:

Full automation of processes:

Cup feeding → Cup pressing → Filling → Sealing → Misalignment correction (Photoelectric tracking/Pattern alignment) → Film cutting → Waste film recycling → Cup ejection

Innovative upper-mounted design: Transmission mechanisms and electrical components concentrated in top section

Operational advantages: User-friendly interface, stable performance, precise pneumatic control, easy maintenance

Premium components: Japanese/German pneumatic systems and electrical parts (e.g., SMC, Mitsubishi)

Optional integrated coding machine

Applications:

Ideal for filling/sealing:

Jelly • Juice • Yogurt • Ice Cream • Salad • Condiments • Beverages • Chocolate