Designed for fluid and semi-solid food industries, this integrated production line combines filling, sealing, conveying, and palletizing into a fully automated process from raw materials to finished products. Featuring a modular layout, it accommodates diverse containers (boxes, bottles, cups) and product types (sauces, liquid foods, soft products), significantly enhancing production stability and operational safety. Empowers enterprises to build standardized, unmanned smart factories.

Core Components

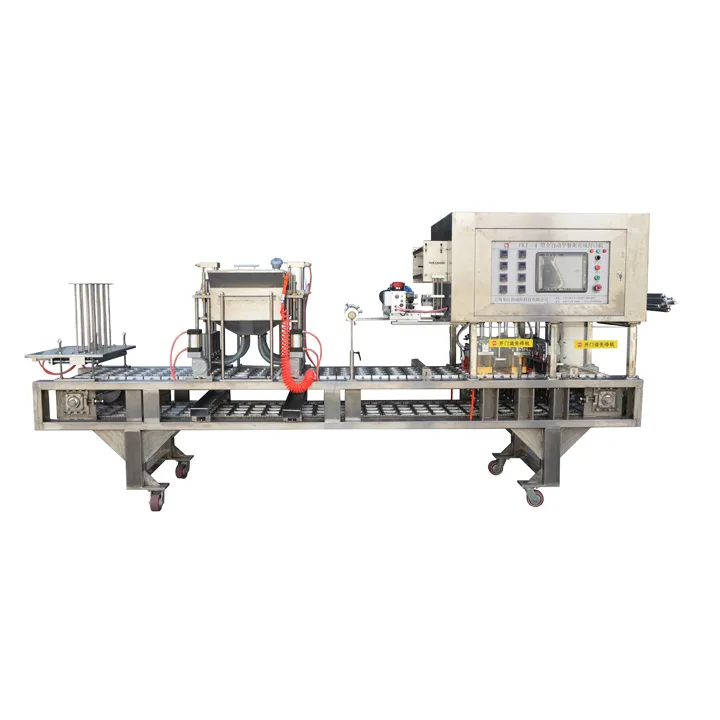

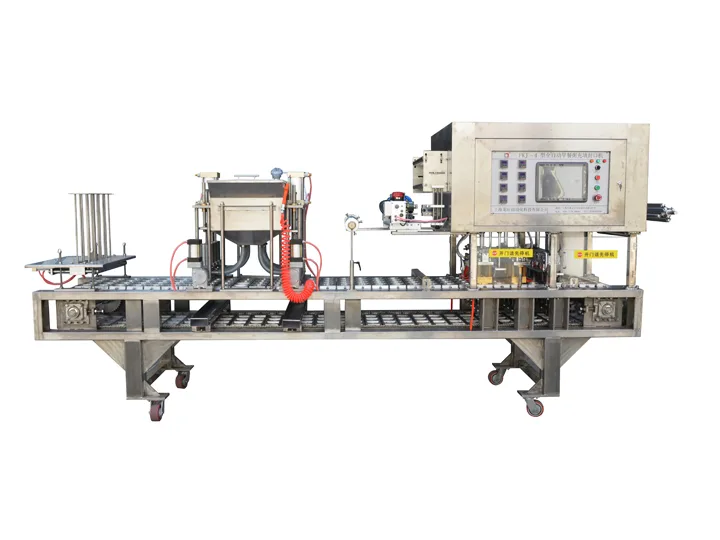

- Automatic Filling & Sealing Machine

Precision filling for liquids, pastes, and semi-solids (jams, yogurt, tofu, pre-made dish sauces)

Filling accuracy ≤±1%

Heat sealing or ultrasonic sealing options available

Compatible with PE, PP, aluminum foil films

Seal integrity rate ≥99.5%

- Inclined Conveyor Belt

Seamlessly connects upstream/downstream processes

Adjustable tilt angle (15°-30°)

Anti-slip wear-resistant belt prevents spills/deformation

Variable frequency speed control adapts to production rhythms

Max load: 50kg/m²

Supports 24/7 continuous operation

- Palletizing Platform

Automatic tray alignment, positioning, and stacking

Intelligent counting system matches tray capacity

Full-tray auto-alert

Customizable stacking modes (3-5 layers or single-layer)

Compatible with plastic/metal trays

- Depalletizing Platform

Robotic arms/pneumatic grippers for automatic unloading

AGV/forklift integration enables unmanned transfer

Photoelectric detection system for empty tray recycling

Closed-loop workflow

Key Advantages

End-to-End Automation

Unmanned operation across filling→sealing→conveying→palletizing→depalletizing

Saves 6-8 operators; boosts efficiency by 70%

Flexible Scalability

Modular design supports add-ons (labelers, vision inspection systems)

Rapid adaptation to new products/process upgrades

Reliability & Durability

Food-grade stainless steel construction

Japanese/German core components

Failure rate <0.5%

Intelligent Management

Central control system monitors real-time data (output, faults, energy)

Cloud-based remote O&M support

Applications

Ideal for large-scale production of:

Jams • Condiments • Liquid Dairy • Boxed Tofu • Konjac Products • RTD Desserts • Hotpot Bases • Pre-made Dish Sauces

Extendable to cosmetic/pharmaceutical fluid packaging

Technical Highlights

Precision Filling

Peristaltic/piston pumps auto-adapt to viscosity

Photoelectric liquid level sensors eliminate leaks

Energy Efficiency

Servo-driven systems reduce energy consumption by 40%

98% automatic waste film/material recovery rate

Rapid Changeover

Pre-saved mold parameters enable ≤20 min product switch

Supports small-batch multi-category flexible production

Service Support

One-Stop Solutions

Line planning • Equipment selection • Commissioning • Training

Customization Options

Container specifications • Capacity (2,000-10,000 units/hour)

Automation level (semi/full-auto • smart factory integration)

From Standalone Machines to Turnkey Lines – Empowering the Future of Efficient Intelligent Manufacturing!

Contact us now for a free production line design proposal & quotation!