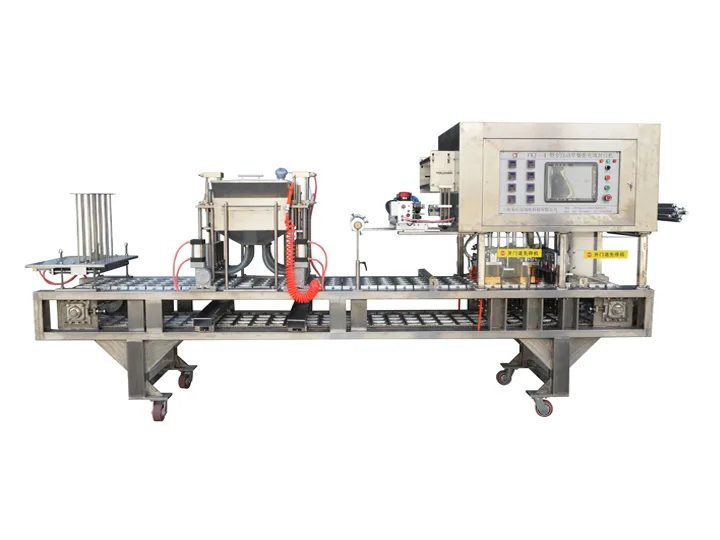

- Equipment Features

End-to-End Automation

Integrated processes:

Cup feeding → Cup pressing → Precision filling → Sealing → Misalignment correction (Photoelectric tracking/Auto pattern alignment) → Film cutting → Waste film recycling → Cup ejection

Unmanned operation optimized for high-viscosity sauces (chili paste, ketchup, salad dressing, etc.)

Sauce-Specific Engineering

Drip-free filling system eliminates residue

Corrosion-resistant hopper & pipelines handle acidic/salty formulations

Reliability & Efficiency

Upper-mounted transmission & electrical components (Mitsubishi PLC, Festo pneumatics)

Intuitive interface with low-maintenance design

Exceptional long-term stability

Smart Flexible Production

Quick changeover between cup/pouch formats (round, square, stand-up bags)

Optional coders/vision inspection systems

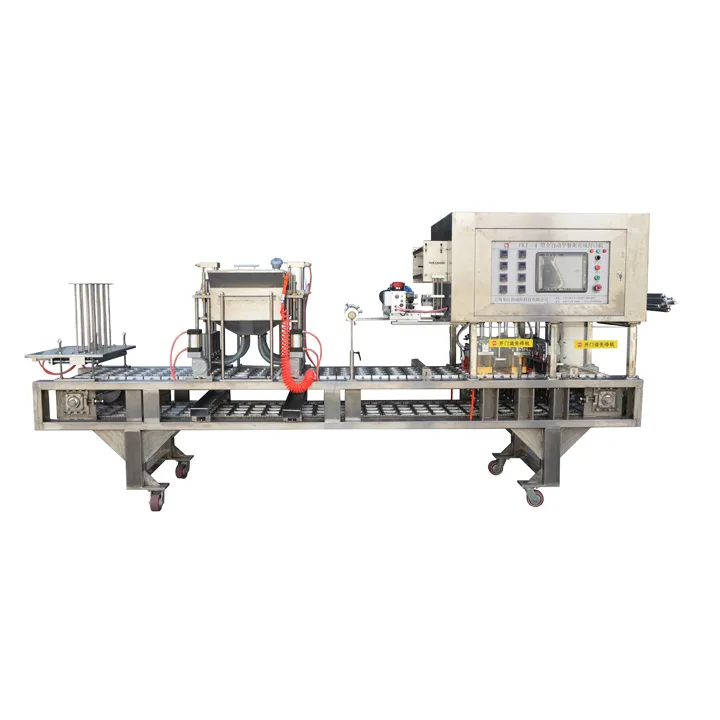

- Core Functions

Key Applications

Sauces: Chili paste, ketchup, peanut butter, hotpot base, dressings

Other Foods: Jelly, yogurt, ice cream, semi-fluid condiments, honey, chocolate spread

Critical Processes

✅ Precision Filling

Servo-controlled filling (±1% accuracy)

Adapts to 30-500mL containers

✅ Leak-Proof Sealing

Adjustable heat sealing (100-200°C)

Pressure-adaptive technology

✅ Intelligent Alignment

Photoelectric tracking ensures pattern consistency

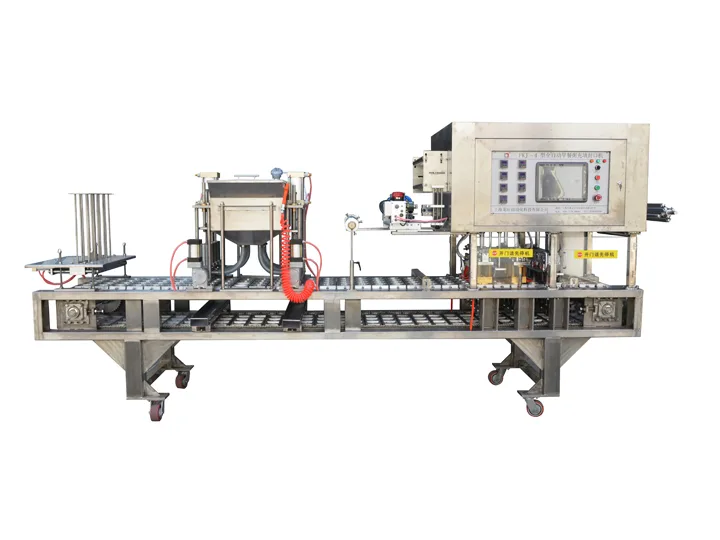

III. Product Advantages

🔰 Hygienic Compliance

Food-grade stainless steel (304/316L) contact parts

Meets HACCP/GMP standards

📉 Cost Efficiency

15% lower energy consumption

Auto waste film recycling reduces material loss

🔄 Enhanced Compatibility

Handles PP cups, aluminum foil, composite films

Custom filling heads for particle-containing sauces

- Target Applications

Food Processing: Meal kit sauces, compound seasonings, RTU sauces

Foodservice Supply: Central kitchen portioning, QSR custom packaging

Emerging Segments: Health-conscious dressings, pet food sauces

Engineered specifically for sauce production, this machine delivers core advantages: precision filling, superior sealing integrity, and corrosion resistance. It overcomes industry pain points—dripping, sealing failures, and cleaning challenges—to enable standardized, large-scale production while enhancing product quality and market competitiveness.