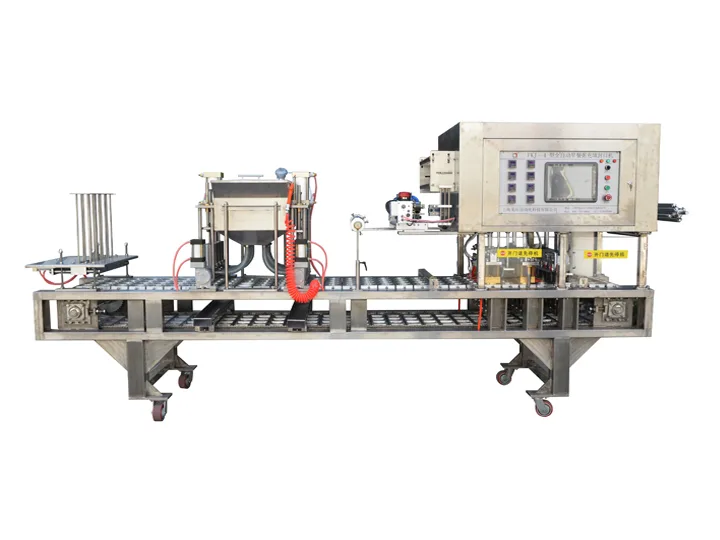

- Equipment Features

Full Automation

Integrated processes: Cup feeding → Cup pressing → Filling → Sealing → Misalignment correction (Photoelectric tracking/Pattern alignment) → Film cutting → Waste film recycling → Cup ejection

Zero manual intervention required

Innovative Structural Design

Transmission components & electrical systems concentrated in upper section

User-friendly interface with simplified maintenance

High Precision & Stability

Premium Japanese/German components (SMC pneumatic systems, Mitsubishi PLC)

Ensures consistent air pressure control and reliable operation

Flexible Expandability

Optional integrated coding machine for date/batch marking

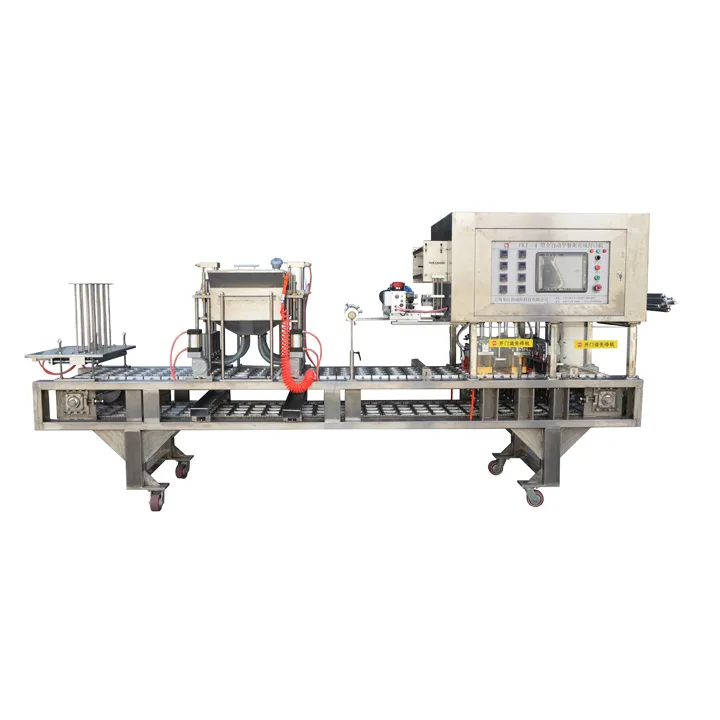

- Core Functions

Applicable Products:

Jelly • Yogurt • Ice Cream • Juice • Condiments • Chocolate • Salad Dressing (fluid/semi-fluid foods)

Key Processes:

Precision filling

High-speed sealing

Automatic pattern alignment

Eco-friendly waste film recycling

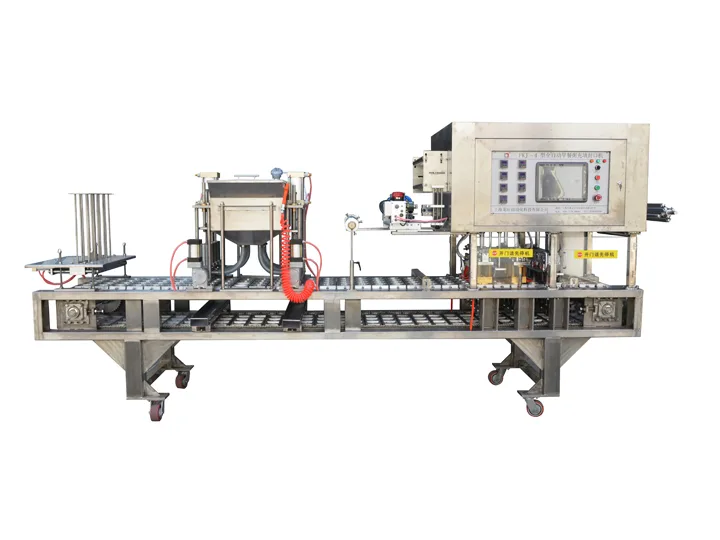

III.Product Advantages

✅ Efficiency & Energy Saving

Automation reduces labor costs by 60%

Waste film recycling minimizes material loss

✅ Easy Maintenance

Modular design for quick disassembly

Critical components accessible for cleaning

✅ High Compatibility

Adapts to various cup types (PP/PS/aluminum film)

Rapid format changeover (<15 mins)

✅ Quality Assurance

Imported core components extend service life

Sealing integrity meets food-grade standards

- Target Industries

Dairy Processing • Snack Food Manufacturing • Condiment Production • Frozen Dessert Sector • Foodservice Supply Chains

Smart design, reliable performance, and flexible scalability make this machine the ideal solution for automated food packaging. It enhances production capacity and product consistency while meeting diverse manufacturing demands.