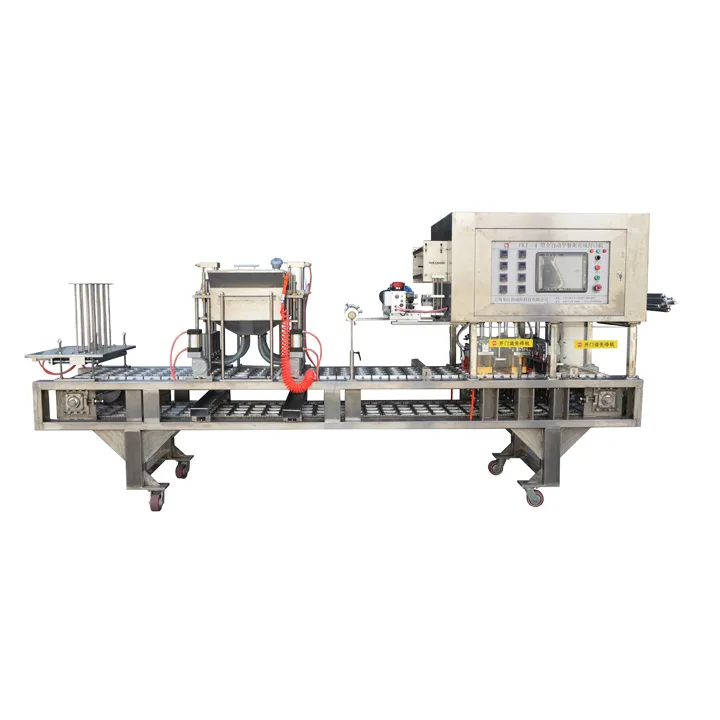

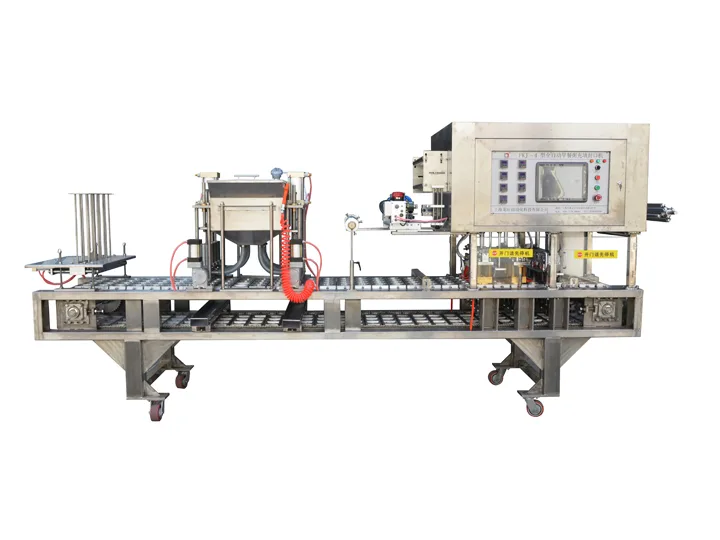

Core Functions & Structure

Aseptic Filling System

Employs Ultra-High Temperature (UHT) processing to sterilize products (milk, juice, plant-based beverages, etc.)

Packaging material (paper-aluminum-plastic composite roll stock) sterilized via hydrogen peroxide (H₂O₂) bath

Maintains full aseptic environment (ISO 14644 Class 5 cleanroom standard)

Automatic Forming & Sealing

Roll Forming: Multi-layer composite automatically formed into tubes with laser precision cutting

Longitudinal Sealing: Vertical seal fin created through high-frequency induction heating

Bottom/Top Corner Sealing: Ultrasonic or thermal sealing forms leak-proof “brick” geometry

Precision Filling Technology

Servo-controlled filling volume (±0.5% accuracy) for 50ml-1L capacities

Non-contact filling valves prevent product contamination

Technical Advantages

Extended Shelf Life: 6-12 months ambient storage without preservatives

Package Integrity: 7-layer composite (PE/Paperboard/Al foil/PE) blocks light, oxygen and microorganisms

High Efficiency: Up to 24,000 packs/hour (e.g. Tetra Pak® TBA series) continuous operation

Intelligent Control: HMI real-time monitoring (temperature/pressure/fill volume) with auto diagnostics

Value-Added Services

Quick-Change Tooling: Rapid transition between pack formats (Standard Brick, Square Brick, Diamond Edge)

Eco Solutions: FSC -certified packaging with 30% reduced carbon footprint

Remote O&M: IoT predictive maintenance minimizes downtime risks

Summary: Tetra Brik packaging machines deliver core values of aseptic safety, high efficiency, energy conservation, and superior protection. As preferred equipment for global liquid food industry leaders, their modular design supports small-to-large scale production lines, enabling premium-quality industrial manufacturing.