Core Positioning

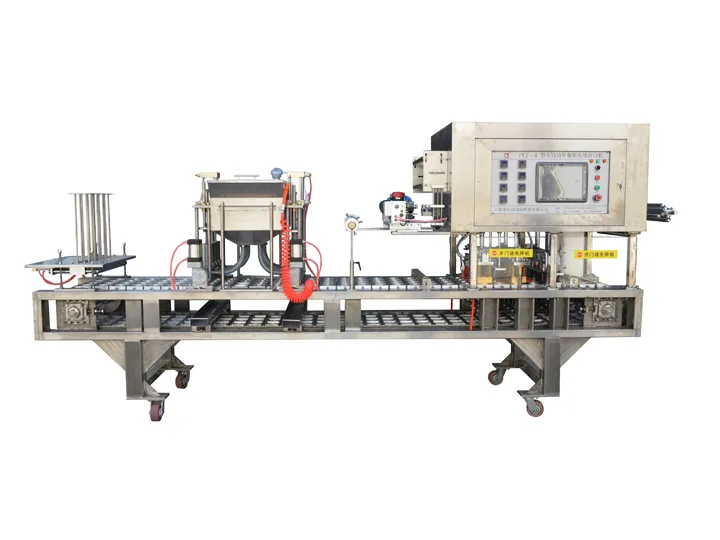

Designed specifically for mooncake manufacturers, this high-efficiency, high-automation, and high-hygiene-standard packaging solution integrates oxygen absorber dispensing to ensure long-term freshness of mooncakes.

Core Functional Highlights

Full-Automatic Sealing

Automatic Feeding: Manually or via front-end equipment (e.g., automatic tray loading machine), place mooncake trays (usually bottom tray + cover film) onto the conveyor belt.

Precise Positioning: Photoelectric sensors detect tray positions to ensure accurate sealing.

Efficient Thermal Sealing: Uses high-quality heating elements and precise temperature control systems for rapid, uniform, and firm thermal pressing (thermal seal or hot melt seal). The sealing line is clear and aesthetically pleasing, with excellent airtightness to block oxygen and moisture.

Cooling and Shaping: After sealing, a cooling device stabilizes the seal to ensure strength and prevent deformation.

Automatic Oxygen Absorber Dispensing

Core Feature: This key function differentiates it from ordinary sealing machines.

Oxygen Absorber Hopper: The equipment integrates a storage hopper for large quantities of oxygen absorber sachets.

Precise Picking & Placing: Adopts manipulators (suction cup type or clamping type) or precise vibration/rotary feeding mechanisms to separate and extract individual oxygen absorber sachets from the hopper.

Intelligent Dispensing: At a specific position before the tray enters the sealing station, the oxygen absorber sachet is automatically and accurately placed into the open mooncake tray (typically beside the mooncake or at a designated location).

Synchronous Control: The dispensing action is strictly synchronized with the conveyor belt and sealing process to ensure each tray receives an oxygen absorber in the correct position without affecting subsequent sealing.

Detection (Optional): Equippable with detection devices (e.g., visual inspection, material shortage sensors) to ensure successful dispensing and prevent missing placements.

Main Technical Features and Advantages

High Efficiency:

Continuous automated operation with adjustable speed (e.g., 20–60 trays/min or higher, depending on model and mooncake size), significantly boosting productivity and reducing labor costs.

Integrates sealing and oxygen absorber dispensing in one step, minimizing process transitions.

High Stability:

Key components (motors, cylinders, temperature controllers, sensors) use renowned brands to ensure long-term stable operation.

Sturdy body structure and precise transmission design reduce failure rates.

High Precision:

Accurate positioning systems and motion control ensure consistent sealing and oxygen absorber placement.

Precise temperature control guarantees stable sealing quality.

High Hygiene Standards:

Food-contact parts use stainless steel (e.g., SUS304), complying with food hygiene regulations.

Design facilitates easy cleaning and maintenance.

User-Friendly Operation:

Human-machine interface (HMI) touchscreen control allows intuitive setting of parameters (speed, temperature, counting, etc.).

Features fault diagnosis and alarm functions.

Strong Adaptability (select models):

Adapts to different mooncake tray sizes and shapes (via mold replacement or adjustment).

Compatible with various oxygen absorber sachet specifications (requires hopper or picking mechanism adjustment).

Ensuring Food Safety and Shelf Life

Airtightness: Ensures tight packaging to prevent mooncake oxidation, moisture absorption, and contamination.

Oxygen Absorption Preservation: Automatically adds oxygen absorbers to continuously absorb residual oxygen, effectively inhibiting mold and aerobic bacteria growth, extending shelf life, and maintaining flavor and texture.

Typical Application Scenarios

Large-scale mooncake manufacturers

Central kitchens/food processing plants

Central factories of baking chain brands

Vendors requiring high mooncake shelf life and packaging efficiency