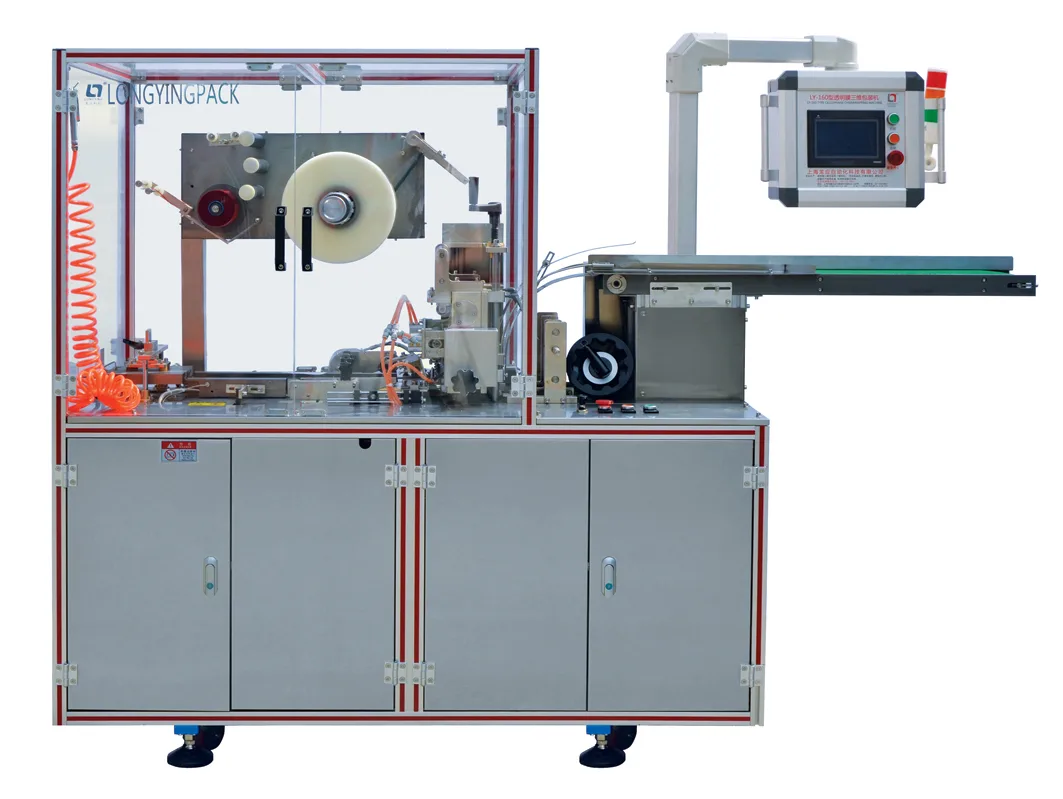

When packaging equipment fails, entire production lines stall. For cosmetics manufacturers running 24/7 shifts, the Longying LY-160 Fully Automatic 3D Film Packaging Machine offers an engineering solution built for relentless operation. By optimizing proven mechanical linkage systems with modern frequency conversion tech, it delivers servo-grade performance without servo complexity – making it the workhorse choice for brands like L’Oréal and Sephora suppliers.

When packaging equipment fails, entire production lines stall. For cosmetics manufacturers running 24/7 shifts, the Longying LY-160 Fully Automatic 3D Film Packaging Machine offers an engineering solution built for relentless operation. By optimizing proven mechanical linkage systems with modern frequency conversion tech, it delivers servo-grade performance without servo complexity – making it the workhorse choice for brands like L’Oréal and Sephora suppliers.

The Mechanical Advantage: Why LY-160 Outlasts Competitors

In high-moisture cosmetics environments, servo motors falter while LY-160’s hardened mechanical core thrives:

Durability Highlights:

⚙️ Forged Steel Gearing: Handles 10M+ cycles without backlash

🛡️ IP54-Rated Electronics: Resists powder/liquid ingress

📈 Proven Uptime: 98.6% operational reliability in 3rd-party audits

Performance Data:

| Metric | LY-160 | Competitor (Servo) |

| Annual Maintenance Cost | $1,200 | $3,800 |

| Mean Time Between Failure | 4,100 hrs | 2,700 hrs |

| Energy Consumption | 4.2 kW/h | 6.8 kW/h |

Precision Meets Flexibility: Cosmetic Packaging Perfected

The machine’s stepless frequency conversion enables microscopic speed adjustments critical for delicate items:

Applies consistent tension on fragile lipstick casings

Prevents cosmetic powder leakage during sealing

Maintains ±0.3mm film alignment tolerance

Application Spotlight: Eyebrow Pencils

Operators can configure:

Variable shrink intensity for wood/composite pencils

Auto-reject systems for crooked film application

Integrated inkjet coding within the film path

Operational Intelligence: Beyond “Fully Automatic”

While classified as automatic, the LY-160 adds smart features rare in mechanical wrappers:

Predictive Maintenance Alerts: Vibration sensors warn of bearing wear

Energy Saver Mode: Cuts power 65% during pauses

Quick-Clamp Film Rolls: Change material in <60 seconds

Why High-Volume Producers Prefer Mechanical Systems

Lower Total Cost of Ownership

No $8,000 servo replacements; off-the-shelf mechanical parts cost 80% less

Disaster Recovery

Mechanical systems can be manually overridden during power failures

Climate Tolerance

Operates flawlessly in 5-40°C ranges (critical for global supply chains)

Expanding Beyond Beauty

The LY-160’s small-footprint design is conquering niches:

Vape cartridge packaging

Medical syringe kits

Premium tea bag boxing

Technical Deep Dive

Film System: Dual-sensor tracking prevents misalignment

Sealing Tech: PID-controlled heat zones eliminate burn-through

Conveyance: Low-friction PTFE guide rails

Conclusion: The No-Compromise Performer

For cosmetics manufacturers prioritizing uptime over flashy tech, the Longying LY-160 represents peak mechanical innovation. It proves that robust engineering, when intelligently optimized, can outperform fragile automation in real-world production.