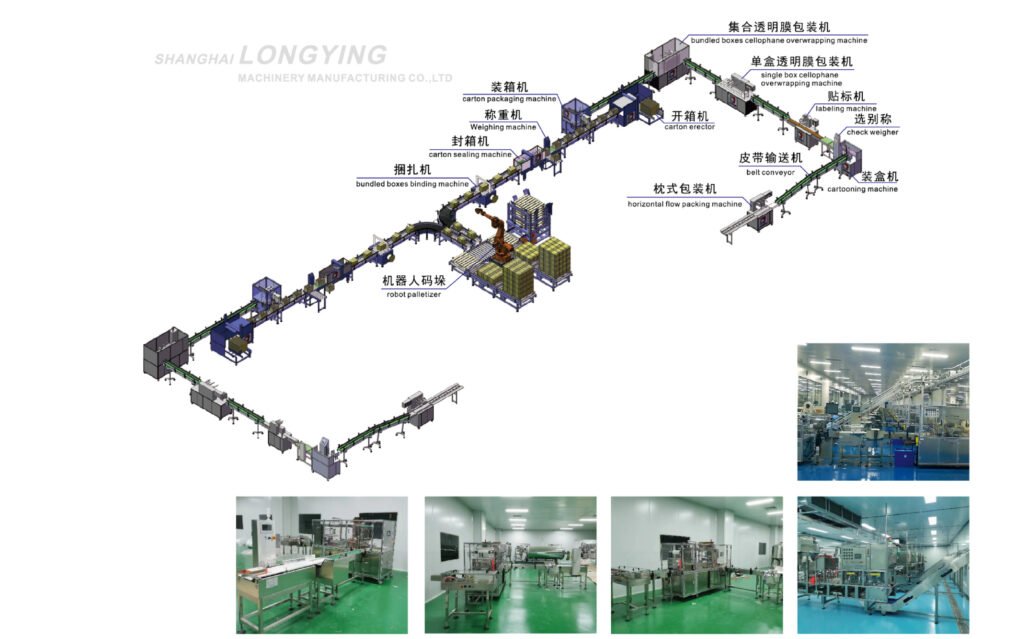

Longying production lines emphasize:

High Cleanliness Design (GMP-compliant),

Modular Structure (easily expandable and maintainable),

Stable & Efficient Operation (high-speed stability with minimal waste),

Comprehensive Quality Control (integrated online weight checks, metal detection, vision inspection systems, etc.).

Widely applied to final packaging of tablets, capsules, ointments, health supplements, and other solid dosage forms, Longying provides pharmaceutical and healthcare companies with efficient, intelligent, and compliant premium packaging solutions.

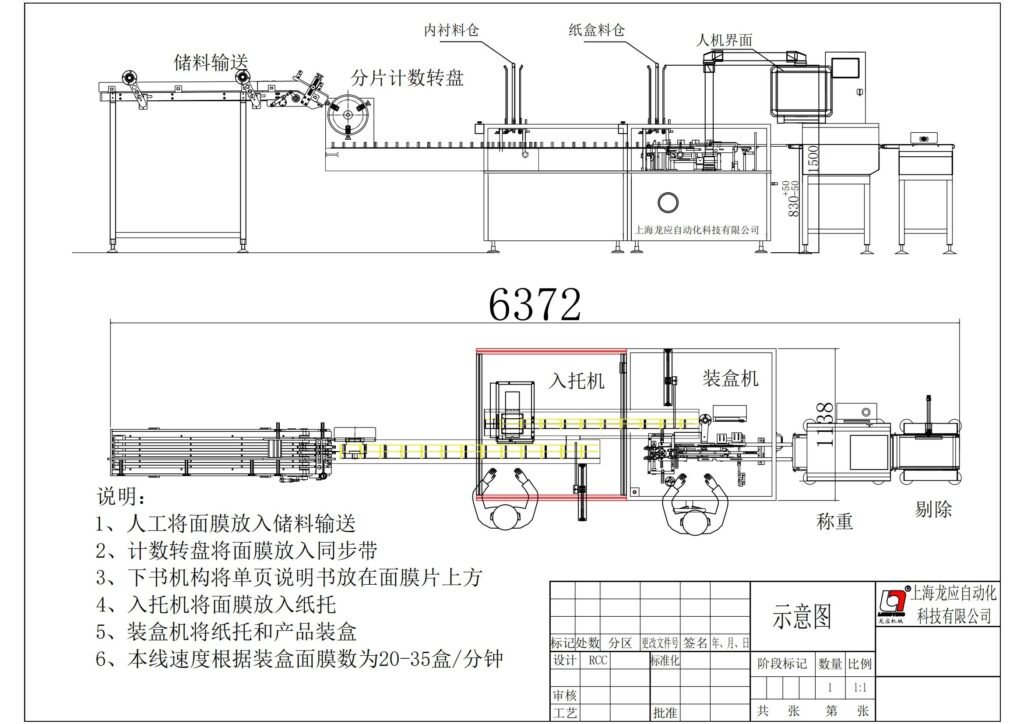

This equipment is primarily designed for the automatic cartoning of ointment bottles (aluminum and plastic bottles).

It automatically completes leaflet folding, box opening and forming, and product insertion, achieving simultaneous synchronization of these three actions. Additionally, it enables automatic batch number printing on box ends.

This equipment features variable frequency speed regulation and PLC automatic control with an HMI operating system, displaying cartoning speed and counts. It enables multi-format adjustment within specified ranges without replacing parts.

An automatic detection system locates and rejects defective products with positioned stoppage. The display shows fault alerts and troubleshooting guidelines.

Key Features & Capabilities:

Precision Application: ±0.5mm placement accuracy for critical pharmaceutical labeling.

High-Speed Performance: Up to 400 products/minute (model-dependent).

Integrated Security:

Tamper-evident label printing

Unique serialization (QR/Data Matrix codes)

Track-and-trace data generation

Flexible Handling: Accommodates bottles, vials, syringes, and folding cartons.

Vision Verification: On-the-fly print quality inspection and position validation.

Key Features:

Integrated Automation: Seamlessly packs sealed cartons into shipping cases

Intelligent Palletizing: Robotic arms layer cases in configurable patterns (column/brick)

High Throughput: Handles up to 20 cases/minute

Multi-format Compatibility: Adjustable for various case sizes (200-600mm) and pallet types (EUR/ISO)

Safety Integration: Light curtains and emergency stops per CE/ANSI standards

Traceability: Automatic pallet labeling with QR/barcode tracking

Longying Pharmaceutical and Healthcare Packaging Line Solution

This integrated solution provides fully automated packaging for pharmaceuticals and health supplements. Featuring robotic cartoning, precision filling, and capping systems, it ensures GMP compliance with automatic batch coding, vision inspection, and rejection of non-conforming products. The line supports versatile formats (bottles, tubes, blister packs) with quick-change tooling, achieving speeds up to 80 packs/min. PLC control with HMI enables real-time monitoring of OEE, while CIP/SIP modules enhance hygiene. Designed for serialization compliance, it reduces changeover time by 40% and minimizes material waste through servo-driven precision.

RunKang Wellness, focused on high-quality health food products, has demanding requirements for packaging efficiency, protection, and appearance. As a permanent partner of LongYing, its core production line utilizes LongYing’s automated packaging solutions:

High-Speed Automatic Cartoning Machine: Precisely and efficiently completes the automatic cartoning of products, inserts, and boxes, significantly boosting efficiency and ensuring clear batch codes.

High-Performance 3D Transparent Film Packaging Machine: Provides elegant transparent wrapping for bottled and boxed health products, delivering excellent moisture and dust protection while significantly enhancing product appeal through its clear display.

LongYing equipment, with its high stability, intelligent control, and deep understanding of pharmaceutical and food-grade standards, perfectly aligns with RunKang’s pursuit of ultimate efficiency and packaging quality. The smooth operation and consistent output of the production line provide a solid foundation for RunKang’s enhanced market competitiveness.

我们愿意用我们的智慧和能力服务社会,成为您值得信赖的合作伙伴。.